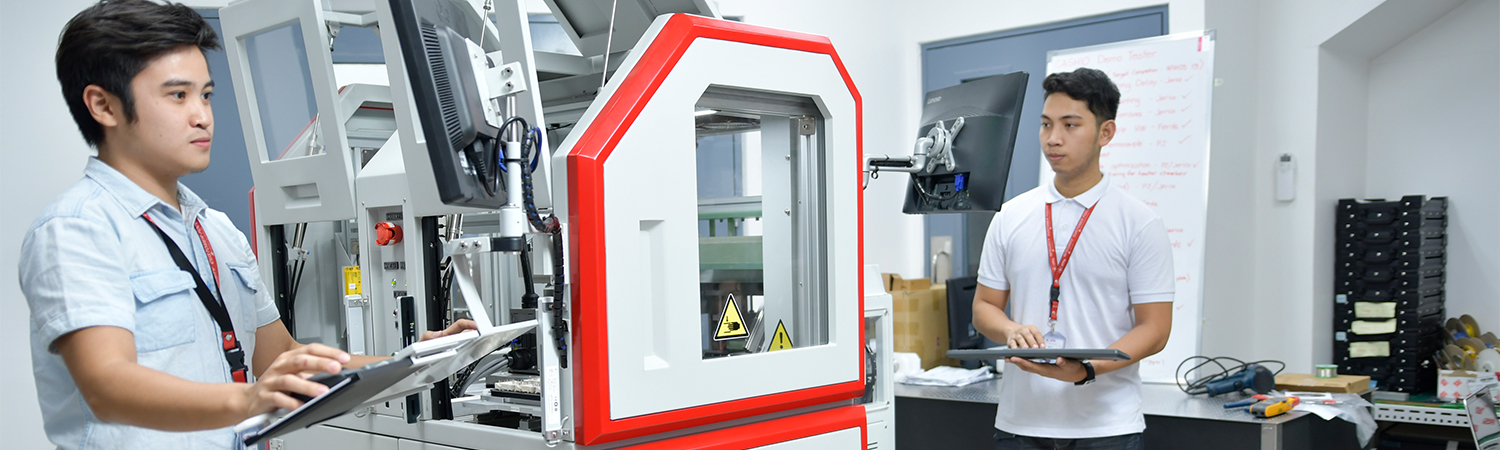

At IMI, our Test and Systems Development (TSD) group is a full-spectrum provider of advanced test solutions, serving industries such as automotive, industrial, medical, and power electronics.

With our in-house development capabilities, seamless automation integration, and global engineering support, we empower EMS clients with fast, flexible, and reliable testing systems.

We specialize in customized test solutions that ensure the highest levels of product quality, traceability, and performance—because at IMI,

“We make TEST your Competitive Advantage.”

Value-Added Services include:

- 24/7 Manufacturing Support: Fast resolution of test/yield issues by in-house experts.

- Engineering Expertise: Over 250 custom testers developed; NI Certified Developers.

- Cost-Effectiveness: Competitive pricing and global supply chain leverage.

- Rapid Development: Standardized fixture designs and software engines for quick customization.

Global Presence

- 5 TSD Innovation Centers

- 70+ Engineers supporting IMI’s global factory network

Development Tools

- Software: NI LabVIEW, TestStand, LabWindows/CVI, C/C++, C#, IMATEST

- CAD: SolidWorks, Autodesk Inventor, AutoCAD

- Vision: NI Vision

APPLICATION AREAS & TEST PLATFORMS

Automotive & E-Mobility

- ECU Testers: Fully automated for steering column units

- Powertrain PCBA Testers: Inverter, CAN, IGBT, MCU programming

- Window Lifter Testers: Robotic automation, LIN bus communication

- Oil Pump Testers: High-current, carousel-based systems

- Run-in Chambers: High-capacity, temperature-controlled testing

Optics & ADAS

- Camera Focus & Alignment: 6-axis active alignment, UV curing

- Intrinsic Calibration: Automated optical parameter recording

- Straylight Testing: Lens defect screening

- End-of-Line Testers: Sharpness, FOV, color accuracy

Lighting & Electronics

- LED Flex Circuit Testers: Luminosity, wavelength, current

- Integrated Backend Systems: ICT, FCT, barcode, robotics

- AOI for LCD Modules: Dual-bay, brightness/contrast adjustment

Power Semiconductors

- IGBT & SiC Testers: Static/dynamic tests, high voltage/current

- MOSFET Testers: Configurable for automation, high precision

- Reliability Testers: Life endurance, thermal cycling, bias stress

![]()

Industrial & IoT

- Wireless Luminaire Controllers: ZigBee, DALI, GSM testing

- Ultrasonic Applications: Multi-board FCTs

- Radiation Dosimeters: Bluetooth, SPI, Wi-Fi testing

- Security Devices: 3-in-1 testers, mechanical & electrical tests

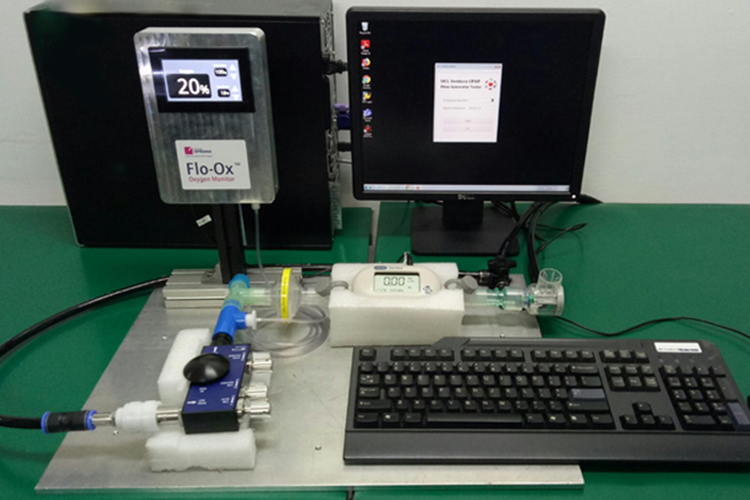

Medical

- CPAP Ventilator Testers: Manual, guided testing with data logging

- Dental PCBAs: Interchangeable fixtures, IR sensor, LED inspection

ADVANCED TEST SYSTEMS

Automated Hot Run-In Test System for Complex ECU Assemblies

At IMI, we engineer advanced, automated test solutions to ensure the reliability and performance of complex electronic control units (ECUs). Our Hot Run-In (HRI) Test System is designed to meet the rigorous demands of high-reliability industries such as automotive, medical and industrial electronics.

Key Features of the MX R13 HRI Station:

High-Capacity Thermal Testing:

The system features 10 thermally insulated towers, each with 9 chambers capable of testing up to 36 ECUs simultaneously under high-temperature conditions.

Self-Heating ECUs:

Each ECU is equipped with power resistors that enable self-heating up to 100°C, simulating real-world thermal stress conditions.

Automated Handling with Robotics:

A high-precision ABB 6-axis robot (150 kg payload) automates the loading and unloading of ECU pallets, ensuring consistent handling and operational efficiency.

Integrated Cooling Process:

After thermal exposure, devices under test (DUTs) are transferred to a dedicated cooling rack to complete the required temperature profile.

Powerful and Scalable Infrastructure:

Each chamber is connected to high-current programmable power supplies (rated at 10kW), ensuring stable and scalable power delivery across all test units.

This system exemplifies IMI’s commitment to engineering excellence, automation, and quality assurance—delivering robust solutions that support our customers’ most demanding reliability requirements.