Cutting components to your exact specifications

We can fabricate and shape various parts of any material into smaller and intricate parts enabling them to fit exactly where you want them.

- Design and fabrication of mechanical parts, fixtures, and related machining activities to support manufacturing at lower cost and shorter lead time;

- Modification and preparation of production materials that enhance productivity and address quality issues.

We take pride in our expertise in machine development, automation, systems integration, and product development, to reduce project cycle time.

EXPERTISE:

- Seamless execution from concept design to fabrication and machine automation

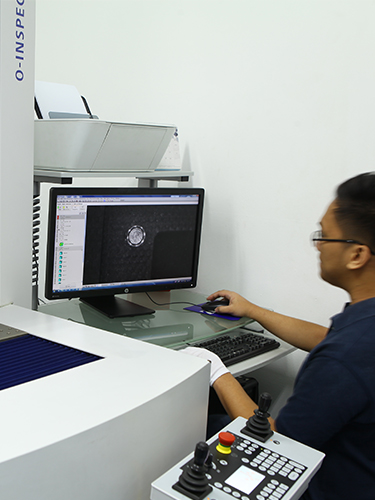

- Complete software solution (CAD, CAM) from design, fabrication and inspection

- State-of-the-art, advanced CNC machines

- Accuracy level of less than five microns on general dimensions

- Databases for WIP, Machine utilization and materials and tools control

- Design solution for fixtures, pallets, jigs, and sheet metal works

- Experienced and highly-skilled work force

- Supports machine design, systems integration and automation

- Design and fabrication of mould for plastic injection

- Competitive cost and faster lead time