More Than a Checkpoint: Why Test Strategy Is IMI’s Competitive Edge

In the electronics manufacturing industry, testing is often seen as a final hurdle—a stage that happens just before the product leaves the factory. But at IMI, test is not the last line of defense. It's a strategic function that begins much earlier and plays a central role throughout the entire product lifecycle.

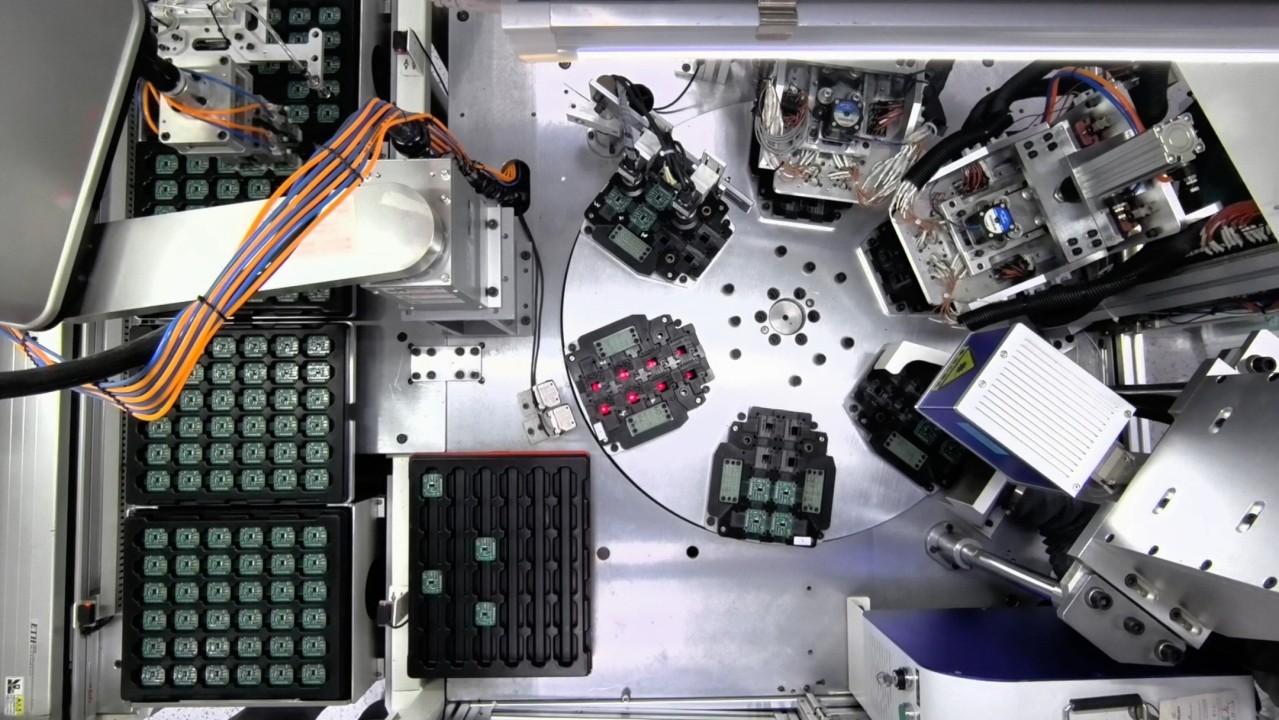

Our Test Systems Development (TSD) team collaborates directly with product architects and design engineers to ensure that testability is embedded from the earliest stages. This forward-thinking approach reduces ramp-up time, enhances quality, and drives down the cost of poor quality (COPQ). Whether it's for safety-critical automotive modules or complex industrial controls, our custom-built test solutions are aligned with production line speeds, diagnostic requirements, and field reliability standards.

We invest in advanced diagnostics, including in-circuit testing, functional testing, power cycling, and EMC compliance. More importantly, we design these systems in parallel with NPI and mass production planning—ensuring scalability, traceability, and compliance with customer and regulatory requirements.

Equally important is how we use test data dynamically across the production process. In-process testing isn’t just a safeguard—it’s a learning mechanism. By capturing data at multiple points, we gain deep insight into process capability over time and under varying conditions. This helps us continuously refine both the manufacturing and test processes to improve yield, reduce rework, and boost reliability.

Even after products enter mass production, we’re still iterating. We optimize test flows, eliminate unnecessary touchpoints, and increasingly focus on how to execute test coverage without added labor. Automation, AI-driven analytics, and modular test platforms all play a role in helping us scale more cost-effectively.

Flexibility is another key pillar of our approach. We’re constantly exploring ways to repurpose and reconfigure test systems to serve high-mix, low-volume product environments. That flexibility is essential as customer needs evolve and product portfolios expand.

At IMI, we don’t just test for defects. We test for insight, process stability, and future resilience. That’s what makes our approach to testing a true differentiator in a crowded EMS landscape.

Author(s):

-

Joey Bantatua (China Operations Head)

Joey Bantatua (China Operations Head)