More than Cost Cuts: How IMI's Component/Materials Engineering, Sourcing and Test Teams Drive Strategic Value for Global OEMs

In today’s manufacturing landscape, global OEMs face constant pressure to reduce BOM costs, shorten lead times, and diversify their supply base (to deal with ever changing global geo political realities)—all without compromising quality, reliability, or performance. But as product portfolios expand and engineering bandwidth tightens post-production ramp, it’s increasingly clear: cost optimization requires more than price negotiation.

At IMI, we take a strategic and engineering-driven approach to sourcing, delivering real and validated cost savings through close customer engagement and a tight integration between engineering, supply chain, sourcing, and advanced testing.

Strategic Sourcing Aligned with Real Engineering Rigor

Our Global Sourcing teams—organized by commodity and region—collaborate directly with IMI Component Engineering teams to identify and qualify alternative components and materials that can unlock substantial savings. We do not just chase the lowest quote; we seek the most strategic supply base—balanced across cost, quality, availability, and risk.

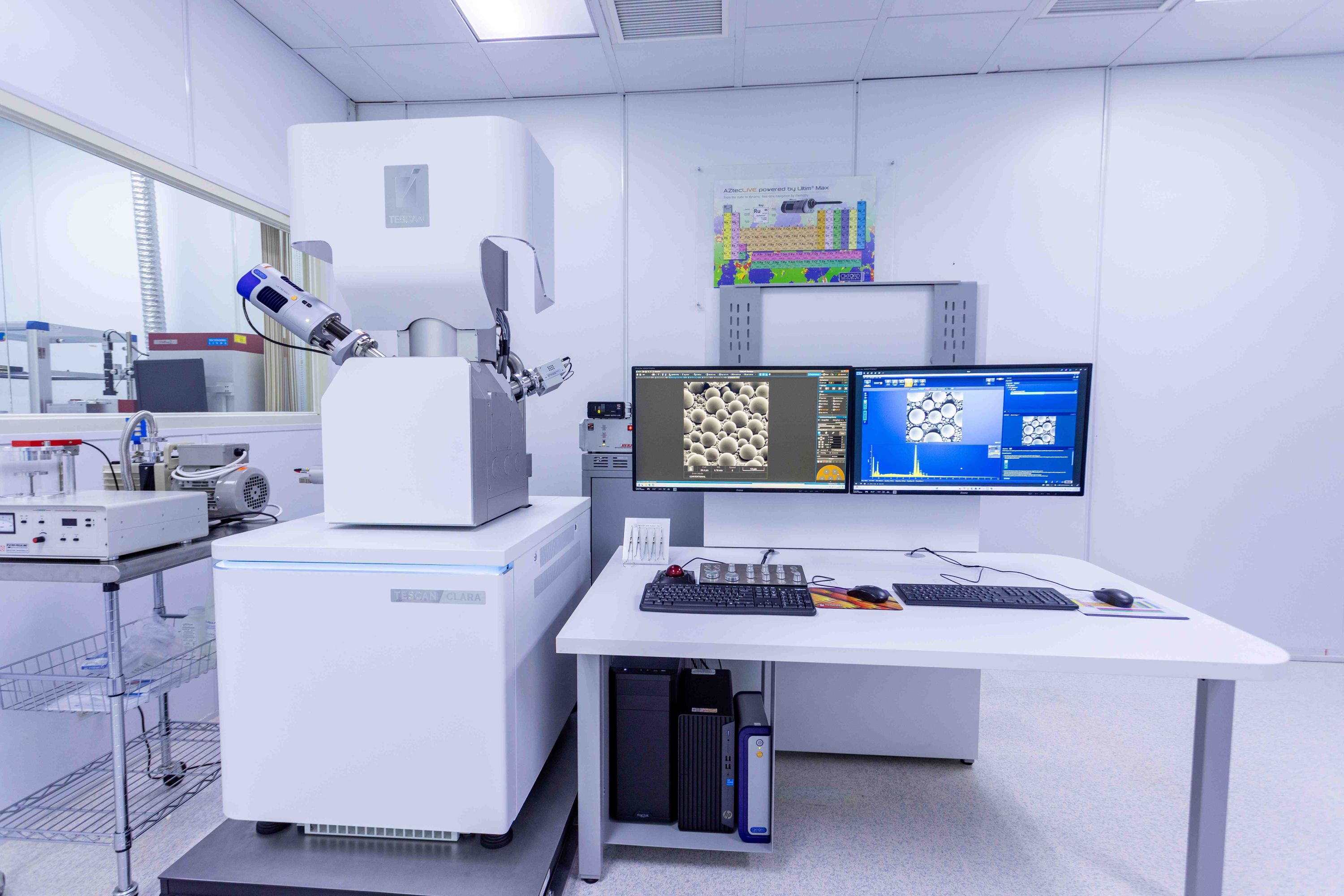

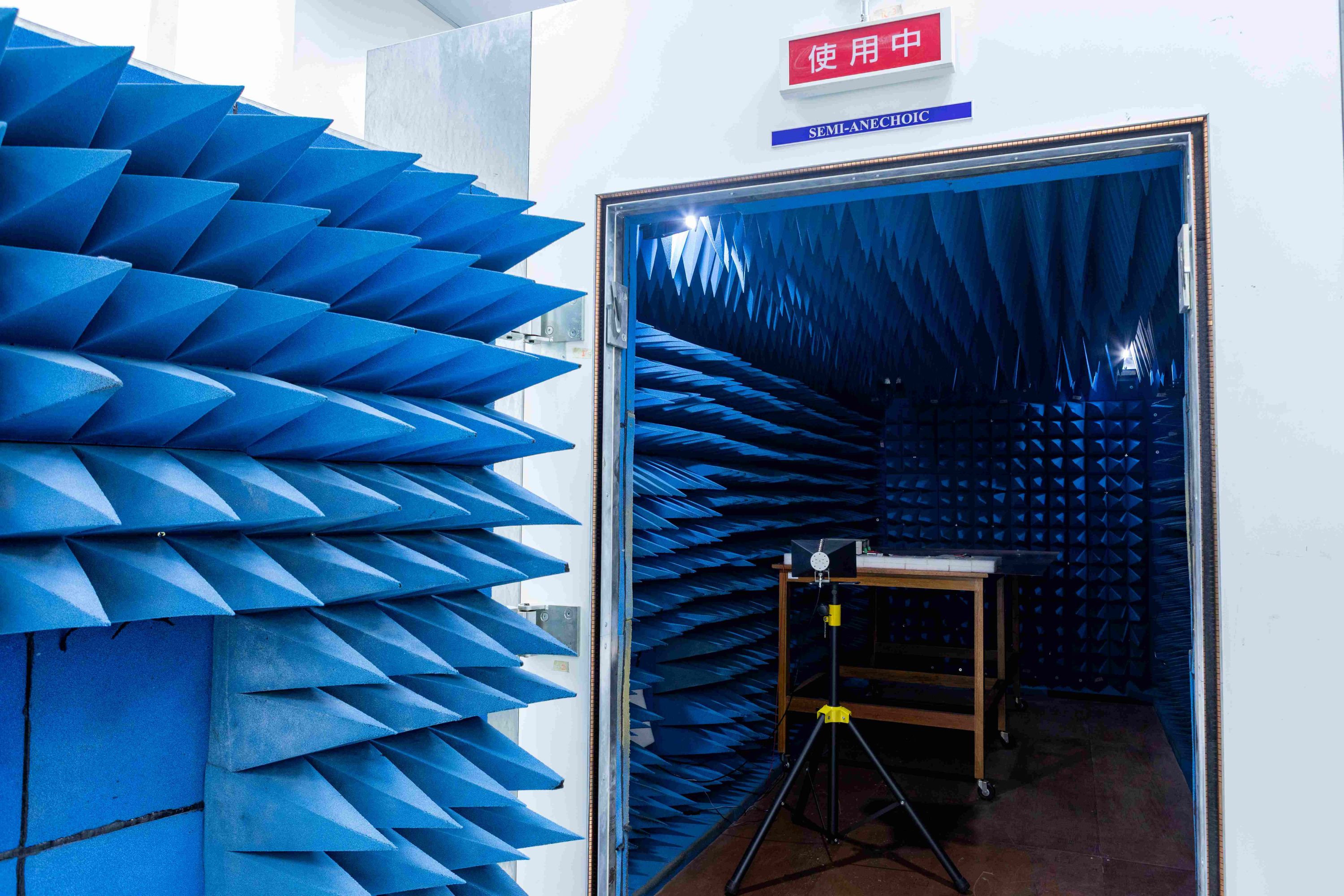

Once a potential alternative is located, negotiated and calibrated with our customer, the real work begins. IMI’s in-house Analytical Testing and Calibration (ATC) Laboratory, an ISO/IEC 17025–accredited facility, performs deep reliability and comparative validation of every proposed component or material change. We analyze down to the elemental and structural level, assessing:

- Thermal and electrical characteristics

- Contamination and corrosion risks

- Failure modes and long-term reliability

- Mechanical and environmental durability under AECQ, IEC, Mil or JESD standards

Our lab capabilities range from FTIR and SEM-EDX to power cycling, vibration testing, and EMC compliance, allowing IMI to provide data-backed assurance that any alternate material or part is fully qualified for the application and meets or exceeds performance expectations.

Solving a Gap Our OEM Customers Can’t Always Fill

Here’s the hard truth: many of our global OEM customers simply don’t have the in-house resources to support rigorous value engineering once a product is launched. After shipping their initial units,OEM engineering teams are typically redeployed to new product development—the OEM’s true engine of growth and innovation.

That’s where IMI steps in.

We fill the post-ramp engineering gap combining our sourcing scale with failure analysis, calibration, and reliability expertise to ensure that cost reduction efforts are strategically validated and not just cost-driven. This gives our OEM partners confidence that any change we propose is not only cheaper—but smarter.

How It Works: BOM Cost Reduction in Action

Here’s a real-world workflow:

- Customer Collaboration: Our account and program management teams work with OEM sourcing and supply chain stakeholders to define cost-down goals and identify target BOM items.

- Supplier Identification: Our component engineering and sourcing team maps alternative sources—often leveraging long-standing partnerships with global suppliers in Asia, Europe, and North America.

- Pre-Qualification Testing: We send samples to our ATC Lab for testing, including ionic cleanliness, solderability, thermal cycling, and electrical integrity checks.

- Side-by-Side Validation: The proposed alternative is benchmarked against the incumbent component using the same test protocols, under the same stress conditions.

- Recommendation Report: We issue a detailed engineering report with risk assessment and cost/benefit analysis, which can then be reviewed and approved by the OEM.

- Qualification and Release: Once approved, the new part is released into production, with change control and traceability assured.

The Result: Not Just Cost Down—Capability Up

This approach delivers far more than “savings.” It delivers:

- Reduced dependence on single-source components

- Improved lead time flexibility and regional sourcing optionality

- Enhanced product quality through rigorous testing insights

- Faster time-to-value on cost reduction initiatives

- Shared engineering ownership between OEM and EMS

At IMI, BOM cost reduction isn’t just a procurement goal—it’s a cross-functional, validated, and customer-centric strategy that strengthens the entire supply chain AND our long term relationships and commitments to and with our global OEM customers. And with our ATC Lab as a core enabler, we’re not just negotiating costs—we’re building smarter, more resilient global products for the long run.

Author(s):

-

Lionel Clouet (Global Head, Supply Chain)

Lionel Clouet (Global Head, Supply Chain)

-

Philippe Antunez (Global Head, Sourcing and Commodities)

Philippe Antunez (Global Head, Sourcing and Commodities)

-

Remy Buogo (Global Head, Advance Competitiveness Engineering)

Remy Buogo (Global Head, Advance Competitiveness Engineering)

-

Joey Garfin (Global Head, Analytical Testing and Calibration Laboratory)

Joey Garfin (Global Head, Analytical Testing and Calibration Laboratory)