How Circular Manufacturing Can Save the World

“Take, make, use, and destroy” simplified principles used in a linear manufacturing system. Industries used this business model for decades, but the world we live in right now demands a different, more circular approach.

Industries around the world are faced with almost impossible challenges such as meeting net zero goals, keeping businesses resilient through uncertain times, dealing with resource scarcity and waste, and rising costs of energy. At the same time, industries must come up with solutions for business growth, productivity, and sustainability. While many of these goals seem to be at odds with one another, these conditions show that a shift in the way things are done needs to happen. Not only does it need to happen, but it needs to be embraced.

For decades, industries have been working with a linear manufacturing system, in which raw materials are taken, products are made, consumers use them, and when the products are no longer needed, they are thrown away. The path goes only one way, with the endpoint being disposal.

Because of this long-time practice, the world now faces problems such as digital waste, landfills overflowing, and a gigantic carbon footprint. To address some of this, circular manufacturing offered an alternative to the linear: what if we closed the gap in the life cycle of products and instead of disposal, we re-used them? Instead of “take, make, and dispose”, we adopt “reduce, reuse, and recycle”?

(Also read: Recycling: Success Stories Around the World)

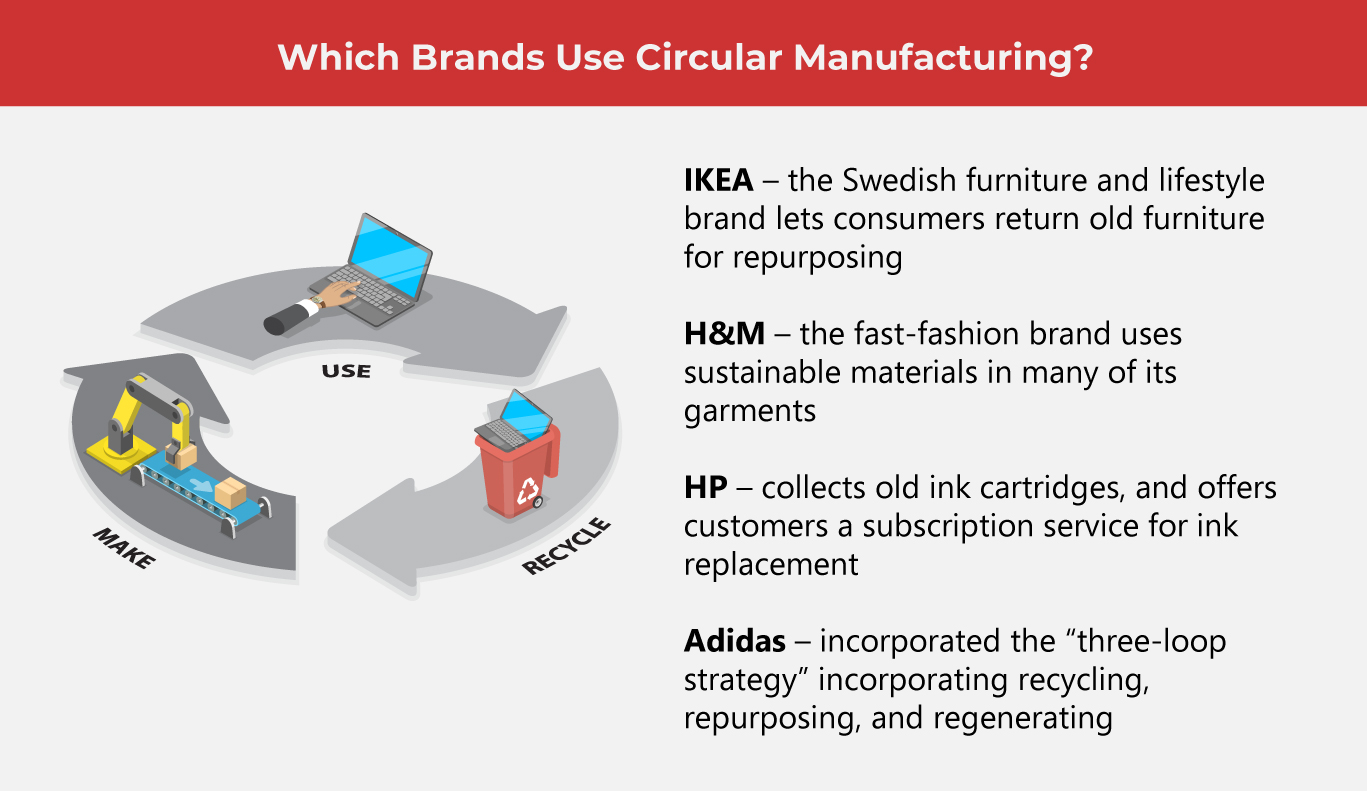

Reusing and recycling is just one basic principle of circular manufacturing, or circular economy, but it’s a very effective introduction to the concept. Plataine defines circular manufacturing as “a production and consumption model whereby manufacturers find means to bring back materials into the economy instead of discarding them.”

Further in the same article linked above, Plataine enumerates how circular manufacturing empowers industries. These are:

- Keeping and re-capturing value from the existing manufactured product

- Reduces demand for scarce resources

- Reduces energy consumption for further manufacturing

In principle and practice, circular manufacturing is not all that new. Many businesses have introduced efforts in the past, whether this be initiatives offering incentives to consumers who “return” products no longer in use for recycling or offering products recycled from other paper or plastic products. However, this is only a small portion of the potential of circular manufacturing.

According to the Circularity Gap Report 2022, only 8.6% of the global economy is circular. In theory, the principles are solid, and it makes so much sense for everyone—from suppliers to manufacturers to consumers to get on board. So how come so little of the economy is circular?

Experts are saying that adopting a circular manufacturing system must be holistic. Because there are so many moving parts in most industries, the principles become complex. Still, cooperation is needed for it to be successful. It isn’t enough for businesses to rely solely on the consumer to be responsible for closing the gaps. Industries need to pick up the slack in terms of organization, practices, expectations, and output. It’s a work in progress, but there are many willing to make the shift.

For example, the automotive industry has the Circular Car Initiative (CIC). The World Economic Forum (WEF) introduces this as a collaboration among thirty OEMs working together to speed up the transition within the automotive industry to circular manufacturing.

While the focus of the automotive industry right now is ensuring a future where we no longer have to rely on internal combustion engines to run our vehicles, many experts say that making EVs is not enough to address net zero goals. The automotive industry can still contribute more through circular manufacturing.

Aluminum parts from existing vehicles can be used to create new EVs. Other components used in manufacturing existing vehicles can be re-purposed to extend their life, even when ICE has finally become obsolete.

The World Economic Forum says, “Circular economy measures, including vehicle sharing, smart charging, refurbishing, repurposing, and recycling, are effective measures to lower lifecycle environmental footprints and costs.”

One OEM taking the reins in the circular economy is Mazda. The company has been involved in the Carbon Circular Economy Council, an organization established in 2021 to promote carbon reduction and recycling. Mazda is incorporating the 3 R’s into its research in vehicle design to make their cars, along with its parts easier for recycling. This also covers the materials being used in the manufacture of these cars—plant-derived biomaterials that contribute to reducing carbon emissions.

Sentiments from industry leaders on the circular economy are the same. It must be holistic for it to work and cooperation is needed. From the top down, a mindset of not being wasteful and using what we already have expands to practices and operations, until it trickles down to how we consume these products. Everyone must pitch in to close the gap. It will take a lot of effort, but it will all be well worth it if we can close the gap together.

As one of the Top 19 EMS companies in the world, IMI has over 40 years of experience in providing electronics manufacturing and technology solutions.

We are ready to support your business on a global scale.

Our proven technical expertise, worldwide reach, and vast experience in high-growth and emerging markets make us the ideal global manufacturing solutions partner.

Let's work together to build our future today.

Other Blog