IMI Jiaxing’s 5 Winning Results from an ECU Line Upgrade

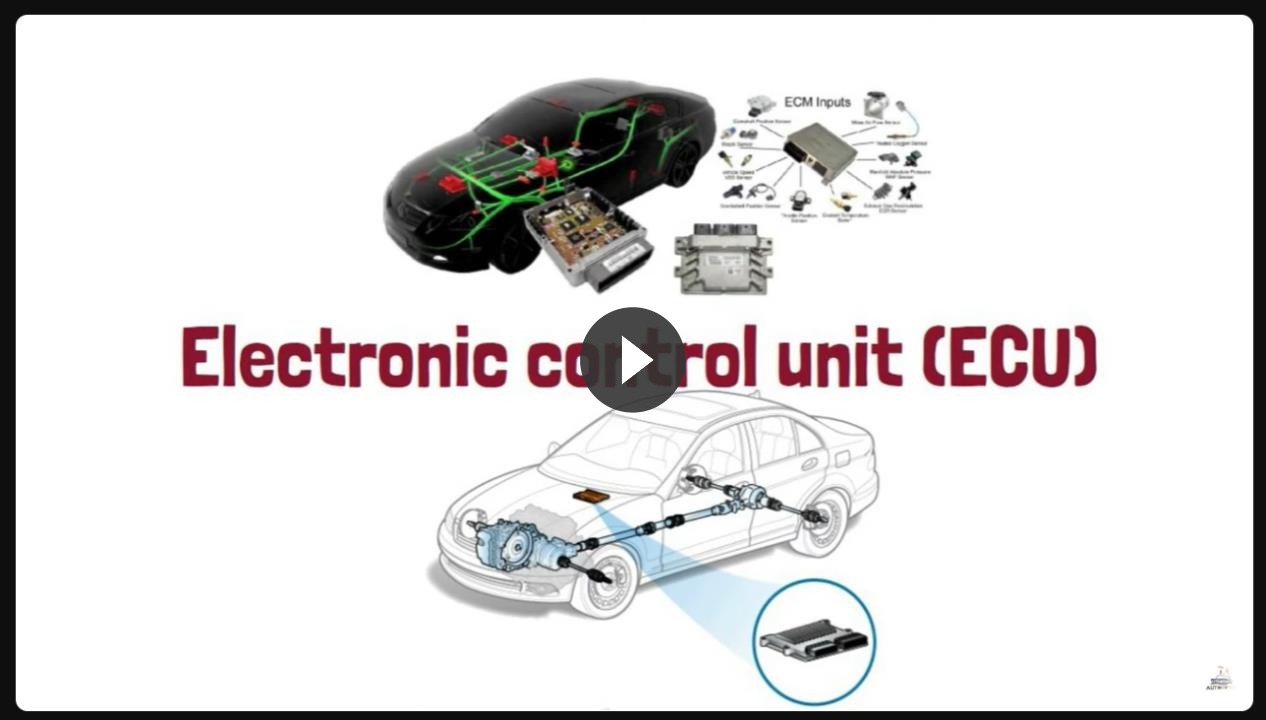

As vehicles become smarter and more efficient, the Engine Control Unit (ECU) has emerged as the core of automotive innovation. Acting as the brain behind the engine, this sophisticated computer continuously monitors performance, optimizes fuel use, and helps control emissions.

Additionally, ECUs play a major role in vehicle safety, driving everything from collision avoidance to advanced driver assistance (ADAS) capabilities. They manage features like airbags and stability systems, while coordinating communication across a car’s many subsystems.

Subjected to rigorous reliability testing, these units are built to ensure consistent performance under demanding conditions—delivering the safety, efficiency, and responsiveness today’s drivers expect.

Core features that power ECU performance

To improve operational efficiency, ECUs are equipped with a range of features that enable real-time decision-making, precise control, and seamless communication across vehicle systems.

- Sensor integration

ECUs gather real-time data from sensors that track engine temperature, airflow, exhaust, throttle, and steering. These inputs support key functions and are validated through testing solutions to ensure reliable performance.

- Real-time data processing

By analyzing sensor input in real time, ECUs can make immediate adjustments that improve engine performance, reduce emissions, and prevent potential problems.

- System communication

ECUs work in coordination with other control units, such as those managing brakes, steering, and infotainment. This level of system integration ensures smooth communication throughout the vehicle.

- Fault detection and diagnostics

With built-in diagnostic features, ECUs can identify issues early, activate warning alerts, and support technicians during maintenance or repair—helping extend the system’s product life profile.

- Adaptive Control Algorithms

Advanced ECUs can adjust over time based on driving habits and conditions. This helps improve fuel efficiency, responsiveness, and overall driving performance, while also enhancing the vehicle’s long-term economic value.

IMI Jiaxing’s ECU Breakthrough

A leading steering ECU manufacturer approached IMI Jiaxing with a complex dilemma: how to double production without increasing headcount. Their existing process relied heavily on manual labor. Operators had to move pallets between a programming bench and a separate test station. Each ECU was handled manually, slowing throughput and raising the risk of human error.

The ECU in question served a critical function in steering control, ensuring that driver input is accurately transmitted to the wheels. Because of its role in vehicle safety, even small errors during testing or assembly triggered full unit rejection, driving up both scrap rates and production costs.

The client also faced limitations with an aging system. While the legacy setup remained functional, it was no longer compatible with new process requirements. Replacing the entire system wasn’t feasible. Instead, they needed to upgrade existing assets and apply a more efficient workflow without disrupting current operations.

What they needed was a partner in electronic manufacturing services—one capable of integrating automation into existing processes while maintaining quality and traceability. IMI Jiaxing stepped in to deliver tailored manufacturing solutions that addressed the client's constraints and prepared the line for higher volumes, all without a complete overhaul.

A tailored fix

To meet the client’s demand for higher output without increasing manpower, IMI Jiaxing—trusted as their outsourcing partner—engineered a streamlined test-and-assembly solution. The team designed a connected line architecture: two automated conveyors feeding into a central test island. This eliminated unnecessary handling, enabling continuous flow and optimized throughput.

A Staubli TX-Series six-axis robot anchored the system. Mounted overhead, it seamlessly lifted units from pallets, placed them into programming sockets, and transferred them to test fixtures. This removed manual steps and ensured consistent, repeatable processes.

Custom IMI-developed software synchronized testing equipment including programmable power supplies, bus analyzers, and sensor simulators for accurate, real-time diagnostics.

The process began with IMI assembling ECUs from engineering samples using semi-automated techniques. After client validation, the approved method was converted into a scalable, automated production line. Every station was designed around a 24-second tact time, derived from the client’s volume forecast with a 20% margin for flexibility.

Still, the system had to overcome key challenges. Tight alignment tolerances meant that even minor discrepancies in materials, equipment calibration, or robot movement could disrupt the process. The line’s closed-loop nature heightened this risk—if one station failed, the entire sequence paused. To meet production targets, the line had to maintain an OEE of at least 80%.

To prevent downtime, the team implemented predictive maintenance, identifying wear-prone parts and pre-scheduling replacements. Floor space constraints were addressed early through simulation, ensuring efficiency without sacrificing layout practicality.

5 benefits of IMI’s automated test-and-assembly solution

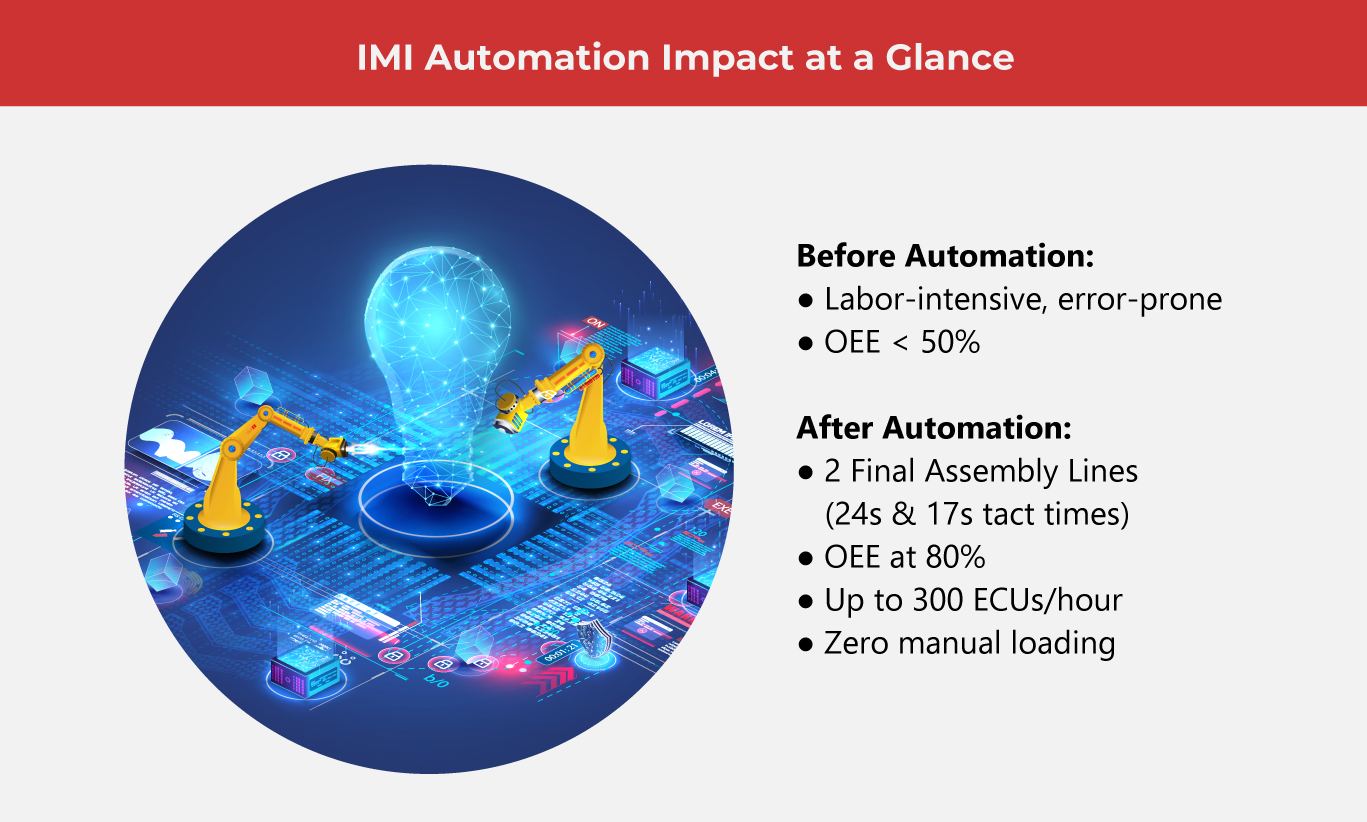

IMI’s solution transformed what was once a labor-intensive, error-prone operation into a streamlined, high-throughput process. Before automation, overall equipment effectiveness (OEE) remained below 50%.

With the launch of two synchronized final assembly lines—running at 24- and 17-second tact times—OEE surged to 80%. These lines now produce up to 300 ECUs per hour, with zero manual loading. The following impacts were felt across multiple areas of the business, from the shop floor to the executive level.

- Increased productivity

The solution replaced eight manual steps with a seamless automated sequence, doubling output without increasing manpower.

- Flexibility

Designed around customer demand and volume variability, the line adjusts production pace while maintaining efficiency.

- Ensured quality

Automation removed human variability, enabling consistent processing, while predictive maintenance preserved equipment precision and uptime.

- Decreased labor costs

Zero manual handling slashed labor requirements, freeing skilled workers for higher-value tasks.

- Customer confidence

With 5.68 million ECUs shipped and no major issues reported, the client’s trust in IMI's quality and delivery capabilities has only grown.

Scalability was a core consideration from day one. The concept is now applied beyond ECUs to other high-volume, stable-model products. Each automated line is tailored to match the customer’s product complexity and forecast, ensuring a reliable, repeatable, and cost-effective solution that scales with evolving market needs.

With a solid foundation in industrial manufacturing, IMI Jiaxing continues to advance alongside evolving manufacturing technologies and industries. Its engineering capabilities support the efficient production of ECUs, helping meet growing customer demands for consistency, quality, and scale. As manufacturing needs shift, IMI Jiaxing remains focused on delivering practical, forward-looking solutions for a dynamic global market.

As one of the Top 20 EMS companies in the world, IMI has over 40 years of experience in providing electronics manufacturing and technology solutions.

We are ready to support your business on a global scale.

Our proven technical expertise, worldwide reach, and vast experience in high-growth and emerging markets make us the ideal global manufacturing solutions partner.

Let's work together to build our future today.

Other Blog