What Will Drive Manufacturing This 2026

In 2025, manufacturing technologies and industries embraced innovations such as digital twins and generative AI, laying the groundwork for continued transformation. As 2026 unfolds, companies are expected to navigate evolving customer demands, strategic AI adoption, and resilient supply chains while addressing workforce skill gaps.

The sector also faces growing pressure to integrate sustainability into operations, driving investment in automation, smart technologies, and eco-friendly practices. These eight manufacturing trends highlight the pivotal role of manufacturing markets in global economic growth and underscore the potential for continued innovation and strategic development.

-

Supply chain robustness

In 2026, supply chain management will remain a top priority for manufacturers seeking to protect operations from external pressures. Last year, many businesses adopted reshoring, bringing production closer to customers to reduce geopolitical risks. This trend is expected to continue, supported by nearshoring strategies that balance domestic and international sites. Optimizing each location for different volumes and maintaining high supplier quality will help manufacturers improve efficiency while strengthening resilience across their networks.

(Also read: The Role of AI in Foreign Policy: Strengths & Setbacks)

-

Reliable sourcing

Nearly three-quarters of manufacturers are preparing to raise prices, prompting a rethink of pricing models and economic value strategies. Companies are moving away from fixed formulas, exploring market-driven approaches that better reflect costs and demand. This shift includes forging strategic partnerships and expanding supplier networks across multiple regions. By diversifying sourcing and aligning prices with market conditions, manufacturers aim to enhance resilience and remain competitive in an evolving landscape.

-

Cybersecurity efficiency

As high-profile cyberattacks continue to make headlines, industrial manufacturing is expected to ramp up cybersecurity investments. Many companies still rely on legacy operational technology (OT), leaving critical systems exposed during digital transformation. To safeguard production, firms are strengthening OT and information technology (IT) systems, implementing secure remote access, and improving visibility across operations. Cybersecurity culture is also a priority, with regular employee training and simulated phishing exercises helping staff respond effectively to threats.

-

AI integration

Manufacturers are taking a more strategic approach to AI, moving beyond experimentation to integrate it across operations. According to Xometry, 82% of executives see AI as a core growth driver, using it to optimize everything from maintenance scheduling to supplier risk management. This trend positions AI as essential for competitive advantage, supporting areas such as procurement and quality control. Analysis of these applications is driving smarter decisions and accelerating product development throughout the industry.

(Also read: Language AI & Manufacturing: A Perfect Match)

-

Tech investment

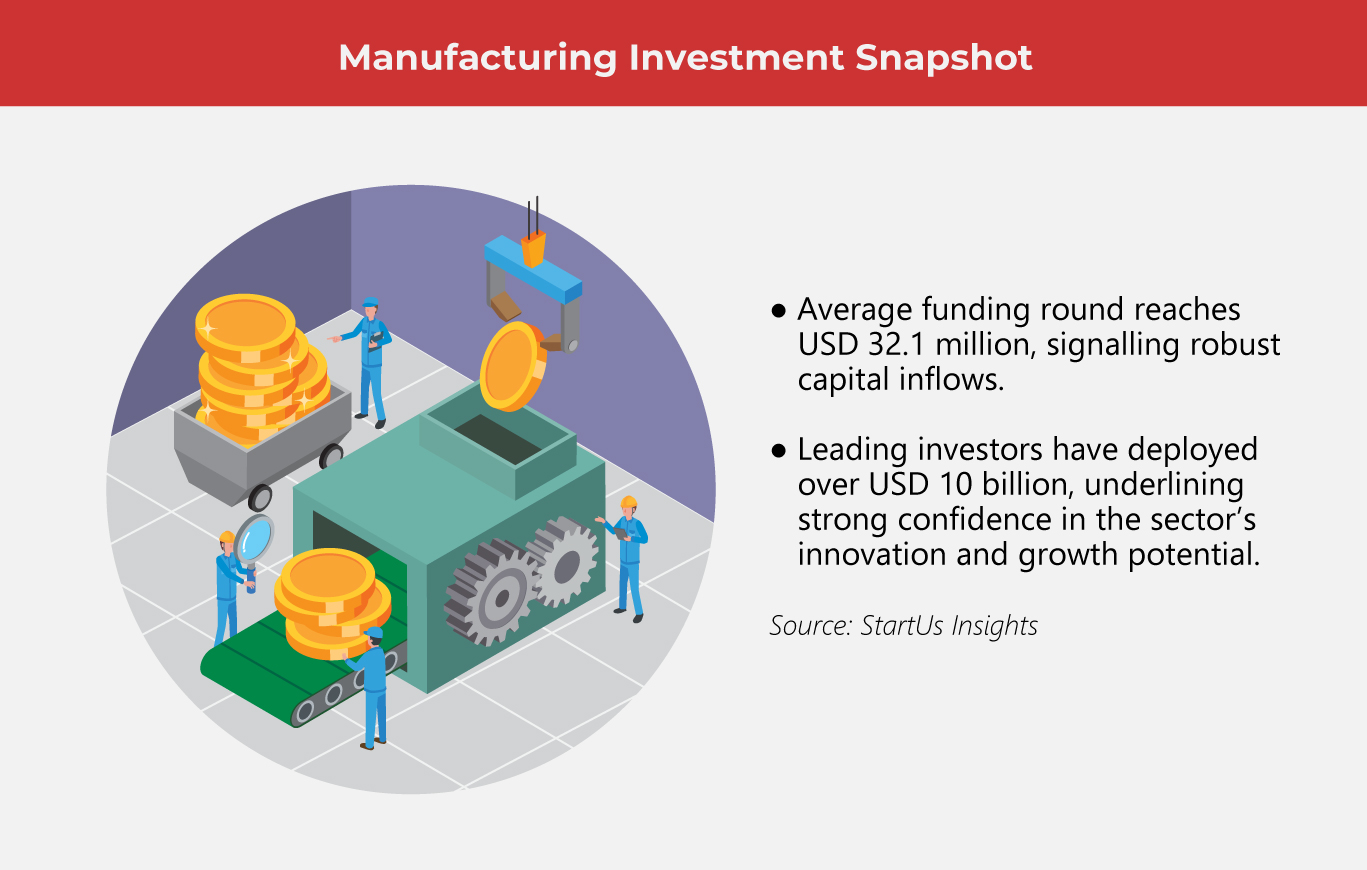

The manufacturing automation and industrial 3D printing sectors are expanding rapidly, reflecting growing investment in efficiency and innovation. Automation systems, spanning 1,800 companies and 106,000 employees, grew 20.8% last year, with firms prioritizing robotics, process optimization, and quality control. Meanwhile, 3D printing continues to gain traction, employing 26,000 people across 800 companies. Capital investments increasingly focus on testing and product validation, ensuring new technologies not only accelerate production but also maintain high standards of precision and reliability.

-

Heightened customer standards

Manufacturers are facing sharper customer demands, with more than half of executives pointing to rising quality expectations alongside pressure for faster delivery and greater transparency. E-commerce is reshaping both B2B and B2C relationships, driving calls for shorter lead times and deeper customization. As a result, companies are adopting market-driven pricing, expanding strategic partnerships, and investing in digital tools that offer real-time production updates and early-stage customer collaboration.

-

Increased agility

Agility is emerging as a defining trend in manufacturing, with industry leaders prioritizing systems that can adapt quickly to disruption and change. Agility is now regarded as essential for competitiveness, as companies work to build flexible digital workflows and improve operational responsiveness in uncertain markets. By strengthening real-time data visibility, cross-functional decision making, and adaptive processes, manufacturers aim to move faster, reduce overhead, and maintain continuity in dynamic conditions.

-

Sustainable manufacturing

Sustainability momentum is building across manufacturing, with positive sentiment translating into steady investment in cleaner operations. Many companies now prioritize clean power as the most impactful green solution, driving growth across the renewable energy market. The trend spans 2,800 firms worldwide employing more than 312,000 people, underscoring its scale. While adoption remains gradual, rising confidence in green technology signals that sustainable practices are becoming a core part of long-term manufacturing strategies.

Manufacturing at a turning point

The manufacturing sector enters 2026 with renewed resilience, pressing forward despite economic uncertainty and operational headwinds. Innovation is being powered by a growing focus on sustainable practices, automation platforms, and the accelerating adoption of industrial 3D printing, all of which are redefining how products are designed, built, and delivered. These shifts are helping manufacturers operate more efficiently while responding to heightened expectations around environmental responsibility and product quality.

At the heart of this transformation is the widespread use of digital twins, AI-driven processes, and circular production models. Together, these technologies are enabling manufacturers to simulate production environments, predict maintenance needs, and redesign workflows that minimize waste. Circular manufacturing approaches, in particular, are gaining traction as firms seek to recover materials, extend product life cycles, and reduce dependency on virgin resources.

Looking ahead, the industry’s competitiveness will increasingly depend on how effectively advanced technologies are integrated into day-to-day operations. Companies that succeed in aligning automation with data intelligence and sustainability goals will be better positioned to improve productivity, control costs, and serve increasingly complex global markets. In this evolving landscape, manufacturing is no longer defined solely by output, but by how intelligently and responsibly that output is achieved. As one of the Top 20 EMS companies in the world, IMI has over 40 years of experience in providing electronics manufacturing and technology solutions.

As one of the Top 20 EMS companies in the world, IMI has over 40 years of experience in providing electronics manufacturing and technology solutions.

We are ready to support your business on a global scale.

Our proven technical expertise, worldwide reach, and vast experience in high-growth and emerging markets make us the ideal global manufacturing solutions partner.

Let's work together to build our future today.

Other Blog