Language AI & Manufacturing: A Perfect Match

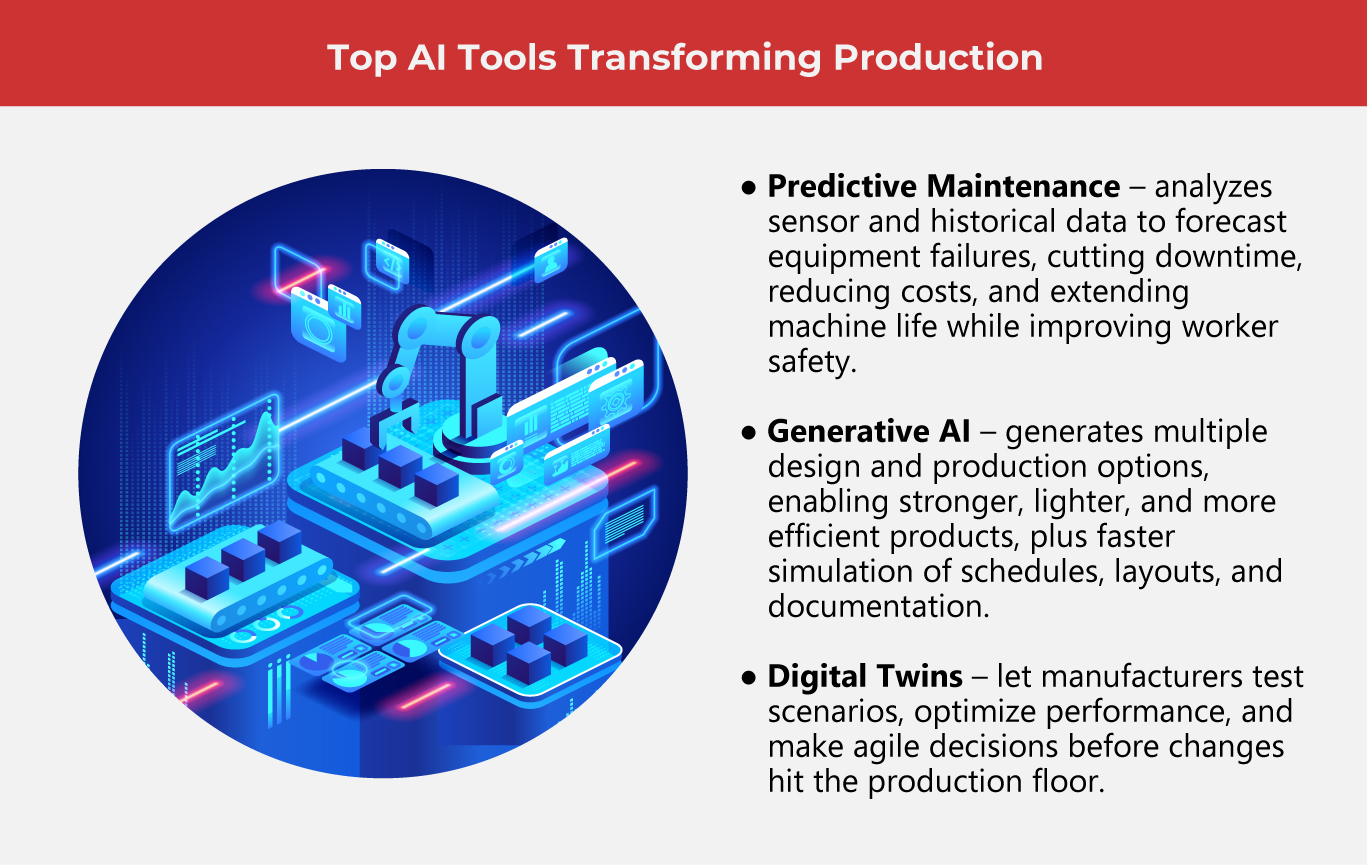

Artificial intelligence (AI) is reshaping manufacturing excellence by removing communication barriers and sharpening operational efficiency across the factory floor. Real-time language translation now allows teams in different regions to collaborate seamlessly, while AI-driven systems analyze machine performance, workflows, and energy use to pinpoint inefficiencies. Acting like a tireless operations manager, AI supports predictive maintenance, strengthens quality control, lowers costs, and reduces emissions, helping manufacturers move decisively toward faster, smarter, and more eco-friendly production.

Manufacturing is entering a future-ready era as AI becomes deeply embedded in daily operations. Smart machines now process data in real time, support human workers, and guide decisions on the production floor. As a cornerstone of the next industrial shift, AI is reshaping how factories operate, enhancing economic value, sustainability, and global competitiveness across the manufacturing sector.

Top global companies are leveraging AI to transform their operations, including AstraZeneca, a leading global biopharmaceutical company. By applying advanced modeling, machine learning, and generative AI, the company is shortening drug development timelines, reducing material use, and optimizing manufacturing solutions. AI-powered digital twins and human-AI collaboration are also accelerating regulatory processes and helping identify and manage emissions risks across the pharmaceutical supply chain.

(Also read: Continuous Manufacturing Drives Pharma’s Top Growth)

Meanwhile, Jubilant Ingrevia, a global specialty chemicals and life sciences company, has integrated AI and machine learning across its production operations to improve operational efficiency and consistency. The company uses digital twins to monitor and optimize processes in real time, while predictive analytics and IoT systems anticipate equipment failures, cutting downtime by over 50%. AI-driven insights reduce process variability, improve product validation, optimize resource use, and lower energy consumption, delivering both cost savings and a leaner, more environmentally conscious operation.

AI advantages on the production floor

AI’s footprint on the factory floor is growing fast: a survey shows nearly 9 in 10 manufacturers are adopting AI technologies to improve production, quality, and supply chain management, with adoption rising year‑over‑year as companies move beyond pilots into broader deployment.

- Maximized factory performance

AI functions like a nonstop operations manager in global manufacturing, analyzing machines, workflows, and supply chains to remove bottlenecks and boost efficiency. Optimizing equipment, energy use, and production schedules enables 24/7 automated operations and unifies manufacturing processes for smoother, high-performance facilities.

- Elevated product standards

Computer vision powered by AI is transforming quality control, inspecting every product in real time to catch defects invisible to humans. By reducing waste, preventing recalls, and enabling continuous process improvements, manufacturers maintain consistent product development standards and strengthen customer trust.

- Boosted growth and creativity

In research and development, AI examines vast datasets to spark innovative product concepts, refine material choices, and accelerate the overall development process. Generative AI and synthetic data accelerate testing, reduce costly iterations, and enable virtual simulations, helping manufacturers create custom products and new product introductions, and bring innovations to market faster and more efficiently.

- Real-time process management

AI monitors sensors across the production floor, instantly adjusting temperature, humidity, and machine activity to boost consistency and yield. Paired with edge computing, it reacts to anomalies in milliseconds. By streamlining operations in real time, industrial manufacturing companies can maintain high-quality output.

- Inventory control

Forecasting tools now let manufacturing markets keep inventory just right, avoiding excess or gaps. By tracking trends and past demand, materials arrive only when needed, cutting waste, freeing space, and saving money. Operations flow more smoothly, and customers consistently get products on time, boosting satisfaction and efficiency.

- Enhanced workflow performance

Advanced systems enhance manufacturing by automating repetitive tasks, optimizing schedules, and uncovering hidden inefficiencies. Engineers can focus on higher-value work while supply chains become more transparent and responsive. From tracking goods with computer vision to boosting customer service, AI strengthens operational efficiency and elevates overall engineering capabilities.

- Lean and green operations

Smart systems help manufacturers cut energy use, reduce waste, and allocate resources more effectively. By tracking emissions, optimizing materials, and leveraging synthetic data, companies can improve sustainability in real time, meet environmental standards, and appeal to eco-conscious customers—all while lowering costs and minimizing their ecological footprint.

(Also read: 5 Ways Manufacturers Can Strengthen Flood Protection)

Language AI: Accelerating smarter, more agile manufacturing

In today’s globalized manufacturing landscape, language barriers can slow innovation, disrupt collaboration, and complicate problem-solving. AI-powered translation tools are breaking down these walls, enabling seamless cross-border communication, faster workflows, and real-time knowledge sharing. By accurately interpreting complex jargon, proprietary terms, and technical documentation, Language AI ensures that global teams stay connected and productive.

Natural language processing is also bridging the gap between humans and machines on the factory floor. Systems can now understand maintenance logs, production notes, and human instructions, helping workers and machines communicate more effectively. This reduces errors, accelerates troubleshooting, and strengthens overall operational efficiency. In a sector where precision and timing are critical, clear communication is no longer optional—it’s a competitive advantage.

Despite English being the global language of business, only about 20% of people worldwide speak it fluently. For manufacturers, this means that without translation support, effective communication may reach only a fraction of employees, partners, or customers.

Misunderstandings can lead to production delays, quality issues, and higher operational costs. Language AI mitigates these risks, providing secure, reliable, and accurate translations across internal systems, CRM platforms, service portals, and technical documentation.

Manufacturers leveraging Language AI have seen measurable improvements: internal and external communication becomes more transparent, teams work faster in their native languages, and production is streamlined through precise multilingual technical documentation. From manuals to specifications, every stakeholder gains a clear understanding of processes and expectations.

Navigating AI Adoption in Manufacturing

While AI promises transformative benefits, manufacturers face real hurdles in adoption. Security concerns and integration challenges make many cautious, with only 36% of manufacturing employees comfortable using popular chatbots compared to 44% in other industries. Upgrading existing systems can be costly, so solutions must integrate seamlessly with the current infrastructure.

To move forward successfully, organizations need a clear roadmap: assess data readiness, define goals, and build scalable AI frameworks. Collaborative robots offer a practical entry point, learning from humans and enhancing flexibility on the factory floor. Edge computing further strengthens operations by enabling real-time decision-making, improving responsiveness, and protecting sensitive data.

Manufacturers cannot afford to delay. Those who embrace AI strategically, balancing caution with innovation, will gain a competitive edge, streamlining operations, enhancing communication, and driving smarter, faster production in an increasingly complex global market.

As one of the Top 20 EMS companies in the world, IMI has over 40 years of experience in providing electronics manufacturing and technology solutions.

We are ready to support your business on a global scale.

Our proven technical expertise, worldwide reach, and vast experience in high-growth and emerging markets make us the ideal global manufacturing solutions partner.

Let's work together to build our future today.

Other Blog