Why Automation Is a Must for Warehouse Leaders like You

With labor shortages and rising costs squeezing operations, warehouse leaders are under pressure to optimize space and services. Studies show 82% of European decision-makers see automation as key to boosting productivity, yet 57% remain unsure where to start. Forward-thinking managers are turning to smart technologies to become future-ready and stay competitive.

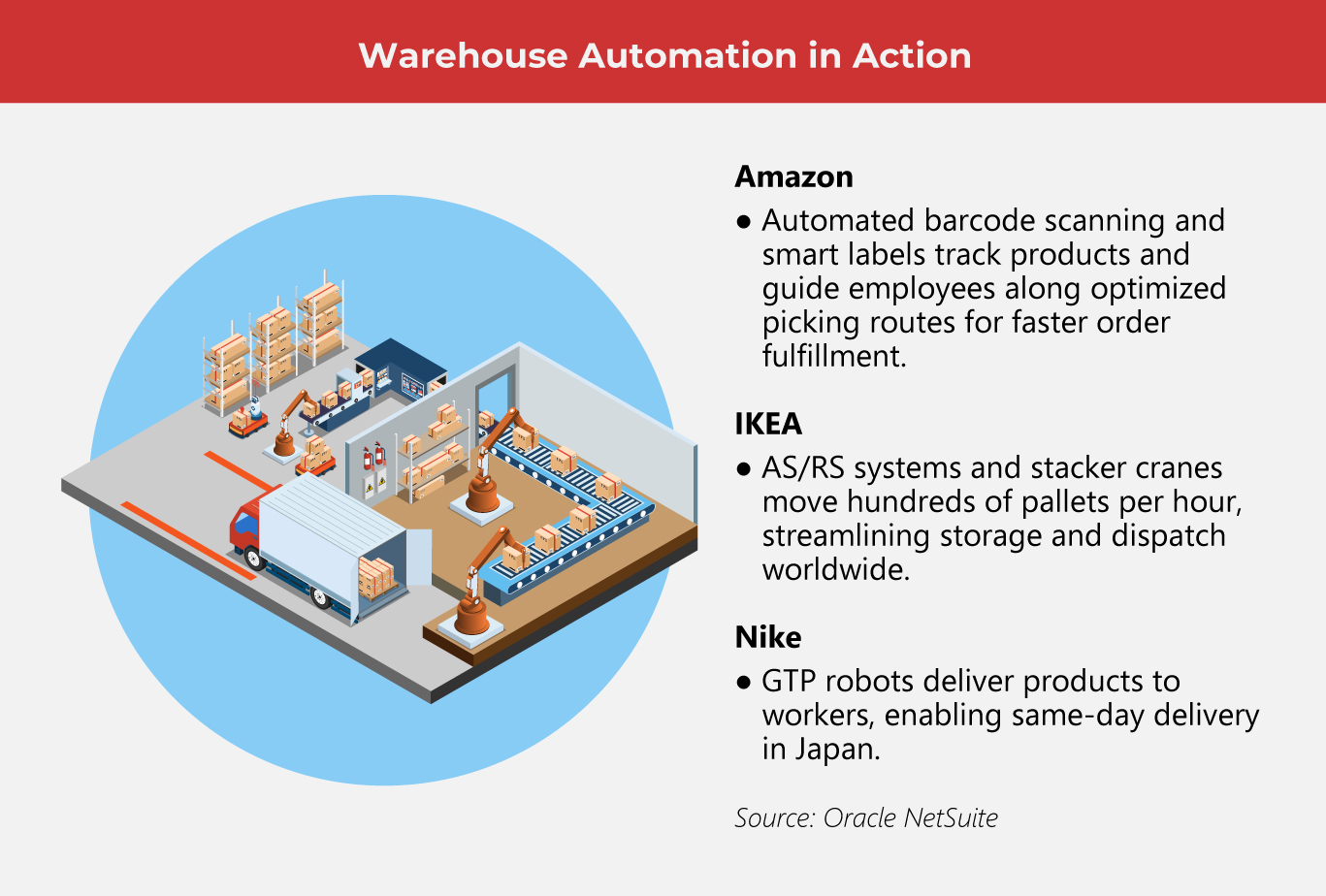

Warehouse automation is transforming manufacturing markets by streamlining the movement of inventory with minimal human intervention. Using robotics, sensors, and software that integrate with existing inventory systems, businesses can cut repetitive labor, and ensure operations meet customer demand. Centralized warehouse management systems boost supply chain management and improve operational efficiency.

With digital and physical technologies, warehouse automation streamlines operations and reduces errors. Digital tools like radio frequency identification (RFID) and mobile barcode scanning integrate with enterprise resource planning (ERP) systems to improve data accuracy while enhancing worker experience. Physical automation, including robotics, cuts manual movement and delivers scalable, reliable workflows.

(Also read: Why You Should Have a Digital Twin for Your Warehouse)

Top 5 warehouse automation trends

As the industrial market evolves, staying ahead means adopting the latest warehouse automation trends that boost productivity.

- Machine vision

Camera and machine vision technology are transforming warehouses, helping operators automate inspections and reduce errors. In Europe, 74% of decision-makers see machine vision as time-saving, while 65% plan adoption within five years. Smart cameras ensure product quality while reducing manual intervention across operations.

- Artificial intelligence (AI)

Data-based insights powered by AI and machine learning drive efficiency through seamless system integration. Predictive analytics optimize inventory, order picking, and task management. Emerging technologies like generative AI further elevate employee and customer experiences and strengthen risk management.

- Robots & cobots

Robotics is transforming warehouses, with mobile robots expected to triple in economic value from $4.5 billion in 2023 to $14 billion by 2027. Meanwhile, collaborative robots (cobots), which work alongside humans, are used for picking and towing by using sensors to navigate environments.

- Blockchain technology

Automated data sharing is vital in manufacturing industries, with blockchain technology enabling secure, transparent, and permanent records across complex supply chains. This advanced digital ledger enhances inventory management, strengthens data integrity, and ensures seamless collaboration among partners within a secure, shared network.

- Sustainability

Some automated warehouses are enhancing efficiency while advancing the renewable energy market. By reducing waste and cutting energy consumption, these smart facilities improve environmental indicators and lower carbon footprints. By leveraging advanced technology, businesses can more effectively achieve their sustainability goals.

(Also read: 8 Reasons Why You Should Use AI for Improving Factories)

Warehouse automation opportunities

By pinpointing tasks for automation, warehouses can strengthen reliability testing and overall performance.

- Inbound & returns processing

Mobile devices let warehouses capture data in receiving areas, feeding integrated software that drives automated workflows. Meanwhile, conveyors and sorting systems streamline return processing, directing items to return-to-stock shelves or storage. Together, these technologies keep inventory flowing seamlessly.

- Inventory selection & sorting

Warehouse order picking is costly and labor-intensive, with travel time taking up work hours. Automated guided vehicles and mobile robots accelerate inventory movement, while Automated Storage and Retrieval Systems (AS/RS) improve accuracy and protect fragile items.

- Stock refilling

Automated inventory tracking and cycle counting can trigger orders when items hit par levels. This type of replenishment reduces overstock, spoilage, and loss, while ensuring shelves are ready for new product introduction. The system keeps inventory balanced and safeguards both stock and revenue.

- Order packing

Efficient order fulfillment relies on smart packing, which balances cost and environmental impact. Advanced systems calculate the ideal box size and materials for each product, considering durability and expense. This approach reduces waste, cuts packaging costs, and ensures items are safely prepared for shipment.

- Dispatch

Automated shipping solutions combine conveyors, scales, dimension sensors, and integrated software to streamline the dispatch process. These systems select the best carriers, calculate rates, and automatically print and apply shipping labels, accelerating deliveries, reducing errors, and improving reliability across the warehouse.

Key benefits

Warehouse automation helps operators cut costs while balancing space, services, and workforce challenges, with over 90% citing efficiency gains as critical to meeting growing demand.

- Faster processes

Automation speeds operations using technologies like AS/RS, autonomous mobile robots, and guided vehicles. By cutting manual handling and directing products efficiently, automated systems accelerate order dispatch. McKinsey reports that such automation can boost warehouse operational efficiency by 20 to 30%.

- Adaptability

By adapting quickly to changing demand, modular robotics and guided vehicles enable scalable operations without major infrastructure upgrades. Amazon’s 750,000 mobile robots cut fulfillment costs by 25%, while Marks & Spencer’s automated warehouse investment aims to double food distribution efficiency.

- Workforce efficiency

Repetitive, physically demanding tasks are handled by warehouse automation, reducing employee strain. Workers can concentrate on higher-value activities like quality checks and exception handling. During peak periods, automation reduces dependence on temporary staff, cutting costs while improving overall workplace satisfaction.

- Inventory integrity

Real-time inventory tracking offers a major operational advantage, giving precise, up-to-the-minute visibility of stock levels. By preventing stockouts and overstocking, it keeps operations running smoothly and ensures orders are fulfilled on time, enhancing customer satisfaction while supporting effective inventory management.

- Better operational output

Advanced robotics and automated systems boost throughput by streamlining order processing and reducing manual handling. These technologies cut bottlenecks, accelerate material flow, and minimize errors, allowing facilities to handle higher order volumes properly.

Signs your warehouse needs automation

Deciding when to automate depends on your warehouse’s workflow challenges and capacity demands. Here are some examples of processes that can benefit from automation.

- Repetitive workload

Facilities managing large volumes of repetitive tasks, like sorting and packing, can benefit from automation. This frees employees to concentrate on complex, value-added activities such as enhancing operational focus, decision-making, and overall productivity across the facility.

- Uniform workflows

Automation thrives in operations with uniform, well-documented workflows. Tasks such as order handling, stock placement, and inventory replenishment are easier to automate when processes are consistent and clearly defined, allowing systems to operate smoothly and reduce errors.

- Expansion needs

Companies facing fast growth and rising order volumes often need to expand operations rapidly. Introducing automation for critical tasks allows facilities to handle higher throughput and surging demand while maintaining smooth workflows and operational consistency without the immediate need for additional personnel.

- Demand for standardized precision

Automated systems deliver reliable, repeatable performance, reducing human mistakes and boosting operational precision. By standardizing tasks, facilities maintain accurate inventory records, streamline order selection, and ensure timely fulfillment. This consistency allows the system to handle routine, error-prone processes with high reliability.

Challenges and Opportunities

Implementing automation comes with hurdles that require careful planning. High upfront costs, technical expertise, system integration, workforce shifts, and potential downtime or obsolescence all add complexity, demanding strategic management and change oversight.

Despite these challenges, automation delivers long-term efficiency, accuracy, and scalability. By handling routine tasks, businesses can boost throughput, reduce errors, and remain competitive, making the investment worthwhile when carefully executed.

As one of the Top 20 EMS companies in the world, IMI has over 40 years of experience in providing electronics manufacturing and technology solutions.

We are ready to support your business on a global scale.

Our proven technical expertise, worldwide reach, and vast experience in high-growth and emerging markets make us the ideal global manufacturing solutions partner.

Let's work together to build our future today.

Other Blog