Flexible Hybrid Electronics: The Next Big Thing in Technology Solutions

July 19,2019,Philippines—Technology has advanced to the point where digitization of manufacturing processes is no longer just an option. With Industry 4.0, the whole global manufacturing industry has no other choice than to adapt to the latest technological advancements including IoT, cloud computing, and human-machine interfaces in order to keep their place in the market.

The growing demand for constant connectivity between humans and the Internet in particular is encouraging the production and consumption of more wearable technology, boosted by flexible hybrid electronics (FHE), which are not only transforming the foundation and process of product design and development, but also the entire landscape of how global technology solutions will work from now on.

In order to stay ahead of the rapid changes in the world of manufacturing, it is important to understand how big of a deal flexible hybrid electronics are in global technology solutions moving forward.

What are flexible hybrid electronics?

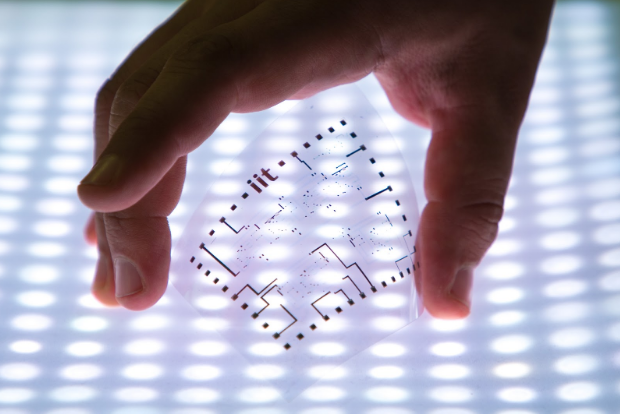

Starting a revolution within the global technology solutions industry, FHE is a departure from the use of traditionally inflexible materials in manufacturing. It is a recent product solution that combines the functionality of rigid printed circuit boards (PCBs) with the flexibility of printed plastic film to create a new category of electronics.

In other words, FHE are electronic devices that use flexible substrates and hybrid component placement in their board design. They present tremendous potential for rollable, foldable displays, as well as smart patches and packaging on paper and plastic substrates.

What are the uses and benefits of FHEs?

FHE allows manufacturers to create affordable and lightweight sensors that can easily conform to the shape or curves of a human body, or stretch across the shape of the object where it will be used while retaining the functionality of traditional electronics. This is mostly beneficial for automation and streamlining of various processes.

For instance, some FHE may contain chipsets and antennas that allow them to communicate with cloud computing systems which makes monitoring of data and acting upon it in real time much easier. In the healthcare industry, specifically for medical electronics, FHE can be used as a wearable tag that can monitor the vital signs of patients and relay data to the hospital’s cloud system which eases the work of the medical staff. More importantly, this can be extremely beneficial for out-patients that need to monitor their health on their own.

FHE can also be helpful in reducing environmental threats from electronic goods since it uses high-performance flexible microwave and digital electronics that consume the smallest amount of potentially toxic materials, according to Crimson Publisher’s article Electronics with Plastics, Foils and Fabrics: The Ensuing Flexible and Hybrid Electronics.

They also have a wide range of applications in other industries including apparel, automotive, aerospace, wireless communications, and even alternative energy.

How is the future of global technology solutions with FHEs?

According to a forecast by ReportLinker, the FHE market was valued at USD 82 million in 2018 and is expected to reach USD 198.9 million by 2024. This provides a positive outlook and plenty of growth opportunities for the FHE market within, especially in the healthcare industry where its purpose is very much needed. It also has a great chance of being the main driver in the improvement of security operations through lightweight robotics, next-generation imaging, and sensing capabilities in EMS Manufacturing in the Philippines and other countries around the world.

Of course, FHE is also facing some problems. It currently has a limited lifetime, is incompatible with the water environment, requires initial investments, and can be challenging for component integration. However, there is no need to worry as the technology is still in its early stages and still has plenty of years to spare for development. More importantly, where it stands now is a good enough starting point for the next big thing in global technology solutions and global manufacturing industry.

Other Blog