Improving the Quality of Solder Joints in PCBs

A common problem in the fabrication of products that demands high quality is the solder joint between the component and pads of the PCB. How can one ensure that the union is firm and adequate? How can one avoid potential cracks? The solution that you may be looking for is the IMC, also known as “intermetallic composites.”

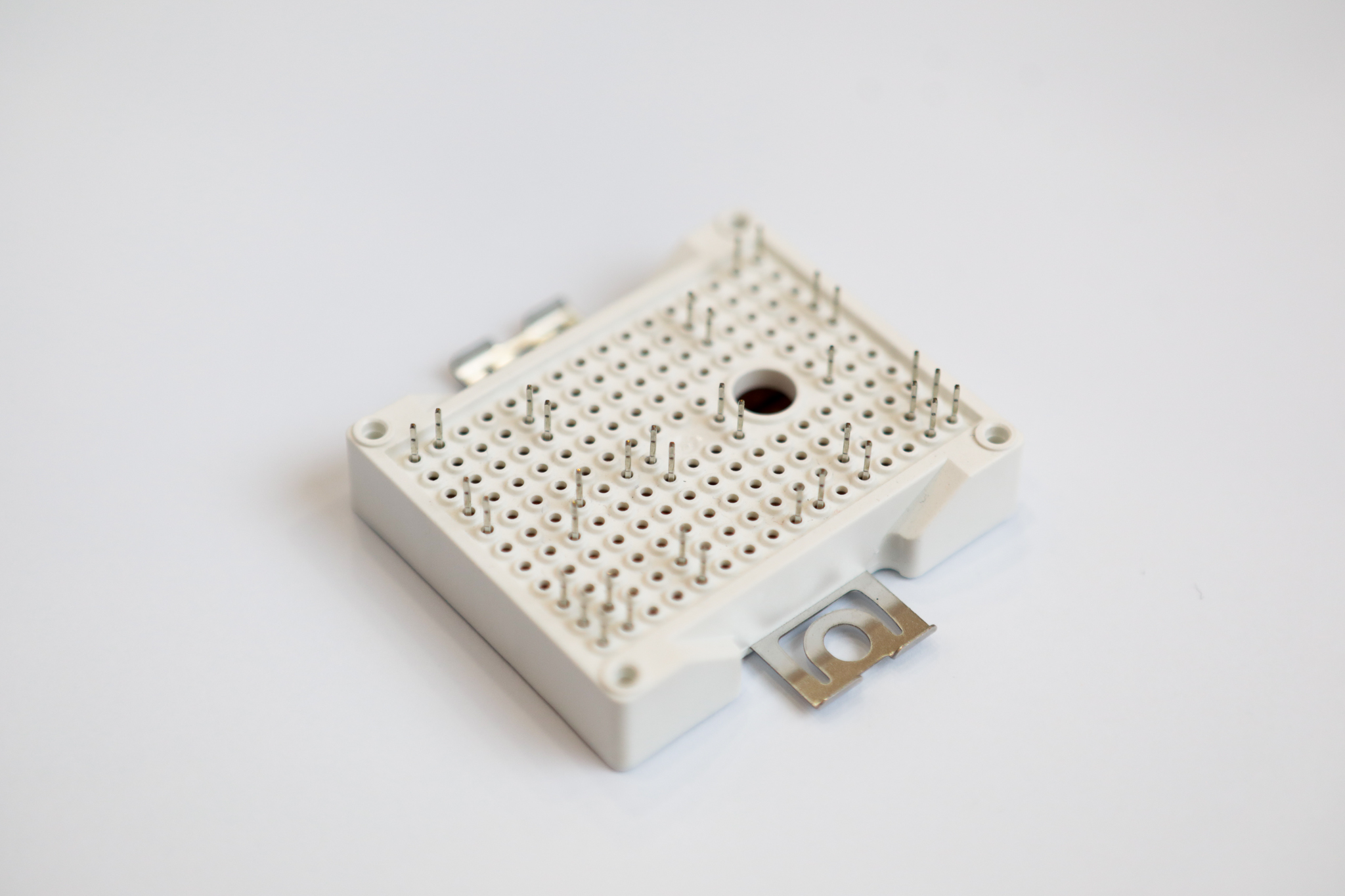

Picture 1.1 IMC in automotive PCBA

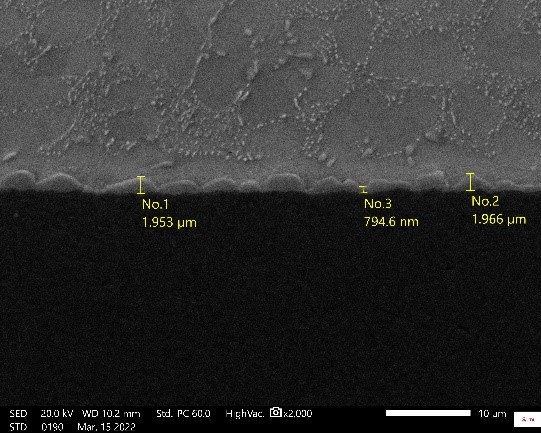

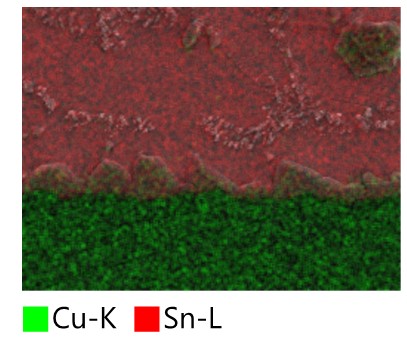

The intermetallic composites are only possible to see in high magnification, between 1000x to 6000x (Image 1.1), but what is it exactly? It is the fusion of two elements due to the high temperature. The combination of the copper and the tin results to a composite under an EDX analysis (elemental mapping) with the two elements already combined.

Picture 1.2 EDX mapping

The presence of IMC in a PCBA is an indicator of good wetting, hence the importance of measuring such.

Currently, there is no standardized acceptance limit for IMC, but the monitoring and analysis of this characteristic in the solder joint is mandatory in most soldering process validation. This is because when the IMC is very large, the solder joint is weak and susceptible to solder cracks. It is also important to ensure that the micro-voids are located between the IMC and the copper land.

Some automotive manufacturers have limits for Cu3Sn and Cu6Sn5 (IMC) that shall be >1µm and <5µm, and the average of IMC measurements should be 2 µm (preferred).

Picture 1.3 IMX MX equipment

At IMI Mexico we offer the services of IMC measurement and analysis, using advanced technology equipment from the high quality brands to ensure that your products are produced with the highest standards and reliability.