A Closer Look at the 3 Scopes

According to WeForum.org, one-fifth of the world's carbon emissions come from the manufacturing industry. The pressure is on manufacturing companies around the world to reduce their total greenhouse gas (GHG) emissions by focusing on what’s called “the 3 scopes”.

Manufacturing companies worldwide are focusing their attention on “the 3 scopes” to manage, measure, and reduce their overall carbon emissions. With each scope addressing different areas of carbon emissions, industry leaders can better review their business practices to identify measures they can put into place to reduce their carbon footprint.

(Also read: Industries and the Race to Net Zero)

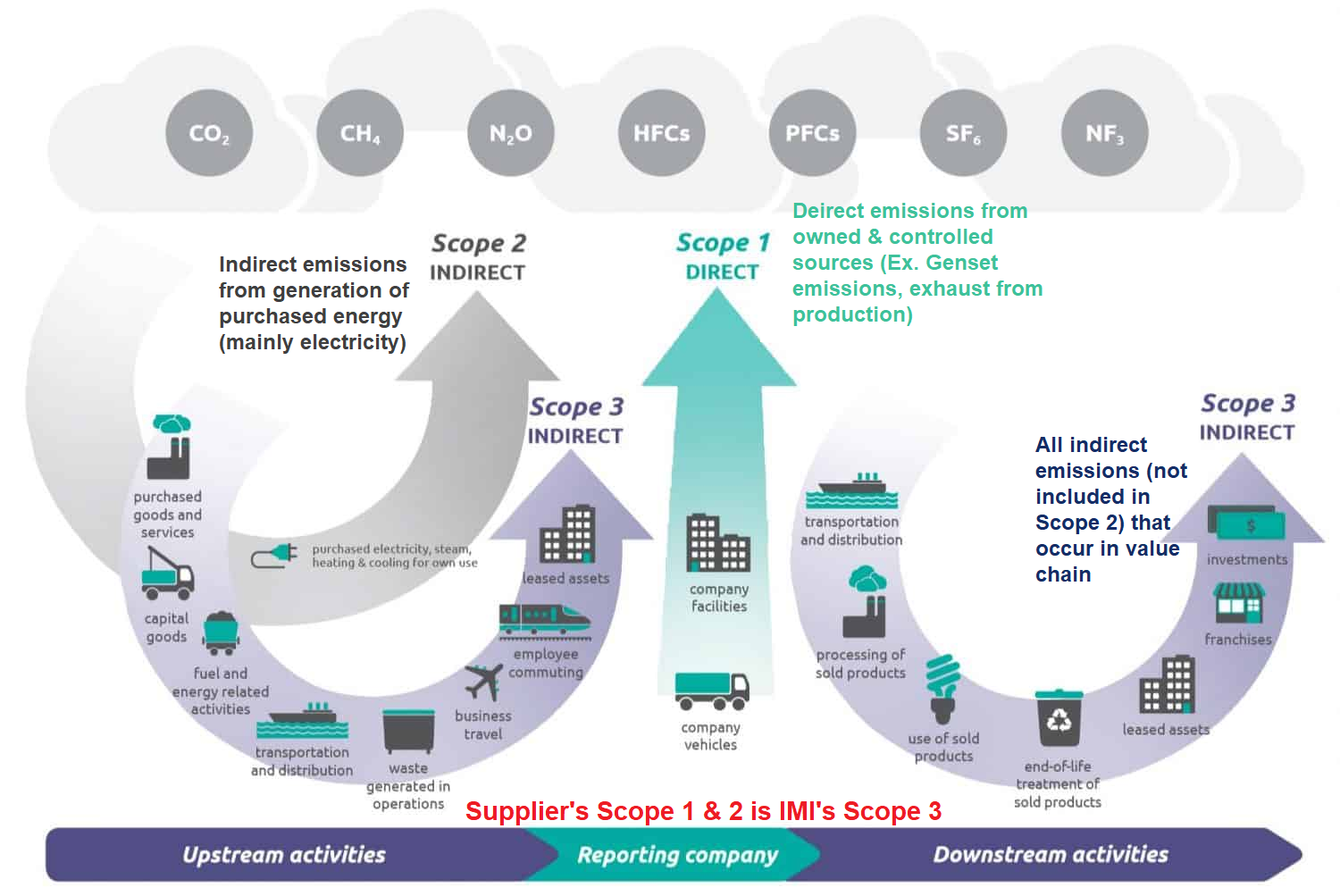

When put into an industry context, GHG emissions are referred to as “value chain” emissions because there are many links in manufacturing that are interconnected and related, though not necessarily run by the same people.

There are upstream and downstream links in the entire manufacturing process, and each link in the value chain will have its own carbon emissions to contend with. The long value chain starts from various suppliers of raw materials and goes down the line to the actual manufacturing companies, and ultimately ends with the end-consumer. We as consumers are part of the value chain, and large companies will have to take into account the carbon emissions that will come from our using the product until the product’s end of life.

To help companies manage the carbon emissions from each of these links, three scopes have been identified.

The United States Environmental Protection Agency (EPA) defines Scope 3 emissions as “value chain emissions”. According to the organization, this represents the majority of a company’s total GHG emissions. It includes all sources or links in the value chain that do not fall within the organization or company’s direct control.

Manufacturing organizations are required to quantify all Scope 1 and 2 emissions when reporting or disclosing GHG emissions, while Scope 3 is not required. However, more manufacturing organizations are working with other interconnected links in their value chain to understand the overall GHG impact of how they run things. Although Scope 3 emissions are not under any of these organizations’ control, each company or link still has a significant influence on the processes, equipment, activities, and practices that will result in emissions. The sharing of information between each organization or link can identify problem areas, such as problematic materials or suppliers, and can then be actionable.

Scope 1 and 2 are the “easiest” for each link to identify and manage because these include stationary combustion machines used on many processing floors. Furnaces, boilers, internal combustion engines, turbines, incinerators, and cooling systems, for example, all contribute to Scope 1 emissions. The EPA even says that the choice of an organization’s transport vehicle can “greatly influence GHG emissions.”

Scope 2 can be a little trickier to understand, but this still falls under the responsibility and control of manufacturing organizations. If Scope 1 includes emissions from processing and production. Scope 2 emissions come from the energy being used for production. Scope 2 emissions come from the purchase of an organization of energy or electricity used for operations.

The World Resources Institute says that “every [energy] generation represents nearly 40% of global GHG emissions, an amount industry is responsible for half of.” This falls under Scope 2 emissions.

When taking these 3 scopes into account, manufacturing organizations can formulate strategies for their business to address carbon emissions. There is no hard and fast rule or set formula mandated by any governing body on how these organizations should reduce their GHG emissions, but there are several overarching principles that most can agree on. It’s only a matter of taking which principles these organizations prioritize and put into action. For many organizations, it’s a combination of methods and objectives.

For example, taking a broad principle such as “reducing energy consumption” and taking the necessary steps to do this becomes a vital step. Companies will have formulated strategies and tactics such as replacing machinery and equipment once these have reached a threshold year to ensure energy efficiency. These must be managed and implemented systematically for them to have a collective impact.

Another strategy that organizations are adopting is reviewing various agreements and contracts they have with energy suppliers. Power purchase agreements (PPA) are essential to managing Scope 2 emissions. An organization may choose to work with other third-party organizations to install and operate an energy system on-site within the organization’s property. This allows the organization to purchase lower-cost, clean and renewable energy from these players. Another strategy is for the organization to produce renewable energy on-site.

Many manufacturing organizations also work with agencies and firms that help crunch and calculate the numbers representing the GHG emissions to address areas of improvement. ClimatePartner.com says that calculating GHG emissions is a critical step and is also a challenge because of data transparency.

The challenge to work with other organizations and share what they know with each other becomes crucial when managing Scope 3 emissions. On paper, the process sounds somewhat straightforward enough, but in the real world, processes and practices are not so black and white. What industry needs to set aside is greed, and focus on what’s really important before it’s too late. That’s the challenge that the industry is facing.

Measures and methods won’t mean much when no one is willing to share what they know and what works for their organizations. Companies need to collaborate and work with each other not in competition, but in a concerted effort to undo what industry has done to our climate.

As one of the Top 25 EMS companies in the world, IMI has over 40 years of experience in providing electronics manufacturing and technology solutions.

We are ready to support your business on a global scale.

Our proven technical expertise, worldwide reach, and vast experience in high-growth and emerging markets make us the ideal global manufacturing solutions partner.

Let's work together to build our future today.

Other Blog