Recycling EV Batteries Help Save the Planet

A UK company is revolutionizing sustainability with a breakthrough in electric vehicle (EV) battery recycling. Altilium’s cutting-edge EcoCathode technology extends batteries' product life profile by transforming old battery waste and production scraps into high-value cathode active materials for new batteries.

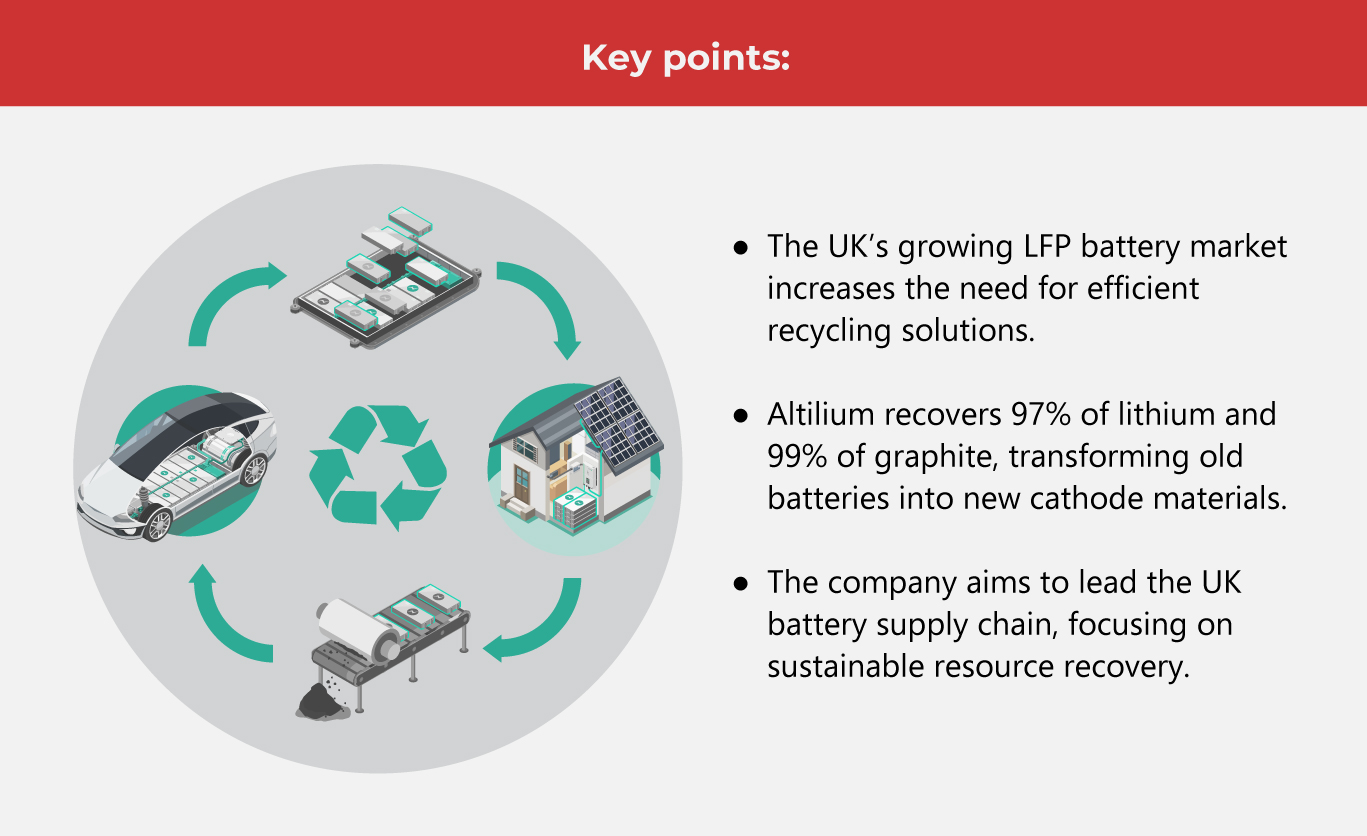

Lithium iron phosphate (LFP) batteries are gaining traction in the electric automotive market for their affordability, safety, and heat resistance. Projected to grow from 18% of the UK EV market in 2027 to 25% by 2035, their rising adoption reflects a move toward greener energy solutions as manufacturers seek to lessen reliance on scarce materials.

Efficient recycling is becoming crucial as LFP batteries gain traction in the market. With the rise of electric vehicles, the automotive sector is creating new opportunities for battery recovery and sustainability initiatives in manufacturing.

UK-based clean-tech group Altilium has taken on the challenge of advancing EV battery recycling with its new LFP battery recovery operations called EcoCathode. By producing cathode and anode materials from old batteries, the company supports the global shift to zero-carbon energy, strengthens energy security, and promotes a circular economy in the automotive industry.

With the renewable energy market expanding and transportation remaining the UK’s largest carbon-emitting sector, concerns over battery production’s environmental impact are rising. The company addresses this by providing low-carbon battery materials, helping automakers cut emissions and advance cleaner mobility solutions.

This ambitious effort is set to transform sustainable battery technology by repurposing batteries from a leading global EV producer. It strengthens the company’s recycling capabilities while assisting automakers in meeting stringent environmental and regulatory standards.

(Also read: Sodium-Ion Batteries: What You Need to Know)

Top 5 benefits of recycling EV batteries

Thanks to its advanced technology, EcoCathode achieves an impressive 97% lithium and 99% graphite recovery from discarded LFP batteries. Through precise material composition analysis, the process ensures maximum resource efficiency while reducing emissions by 24% compared to traditional methods. Other benefits include:

-

Promotes local recycling

Environmental indicators highlight the benefits of local EV battery recycling, including reduced carbon emissions from transportation and lower energy consumption. It minimizes waste, decreases reliance on imported materials, and supports regional economies by creating clean-tech jobs. Additionally, local processing ensures compliance with environmental regulations, reinforcing sustainability efforts and making battery recycling a more responsible and eco-friendly solution.

-

Decreases reliance on raw material extraction

Mining for raw materials like lithium and cobalt disrupts ecosystems, depletes natural resources, and generates pollution. Environmental tests highlight the impact of extraction, reinforcing the need for greener solutions. Recycling EV batteries reduces the need for mining, lowers the incidence of habitat destruction, decreases carbon emissions, and supports a more ethical battery production process.

-

Reduces hazards associated with battery disposal

Improper disposal of EV batteries poses environmental and safety risks, including soil contamination, water pollution, and fire hazards from residual charge. Recycling prevents toxic leakage and reduces landfill waste, ensuring safer handling of hazardous materials. As the industrial market expands, recycling practices protect ecosystems and public health from harmful battery waste.

-

Lower costs in EV manufacturing

Recycling EV batteries enhances their economic value by reducing reliance on costly raw materials. Innovations in recycling technologies, like those developed by Altilium, can drive down material prices over time, making EV manufacturing more affordable. Additionally, expanded recycling capabilities can stabilize second-hand battery pricing, improving accessibility and sustainability within the growing EV market.

-

Better supply chain management

Supply chain issues, including raw material shortages and price fluctuations, impact EV production. Recycling EV batteries helps stabilize availability by recovering valuable materials like lithium and cobalt, reducing dependence on mining and imports. This enhances economic value, lowers production costs, and creates a more resilient supply chain, ensuring long-term growth for the expanding EV market.

(Also read: Why China is Winning the EV Race)

Key Challenges in EV Battery Recycling

EV battery recycling plays a crucial role in sustainability, but several challenges must be overcome to maximize its efficiency and environmental impact.

-

High startup costs

Costly initial investments pose a barrier to the process, requiring substantial funding for system development and advanced technology. Extensive product testing is needed to optimize efficiency and safety, adding to expenses. These financial challenges can slow progress, restricting the growth of recycling infrastructure and delaying the widespread adoption of eco-friendly battery recovery solutions.

-

Vulnerability to supply chain disruptions

End-of-life batteries require a consistent supply chain for efficient recycling, but inconsistencies in collection, transportation, and processing can disrupt operations. Fluctuations in battery availability create challenges in meeting recycling demands. A well-structured network is essential to maintaining a steady flow of materials, ensuring scalable and continuous recycling efforts.

-

Low value of iron and phosphate

The low market value of iron and phosphate compared to nickel and cobalt makes LFP battery recycling less profitable. This financial hurdle limits incentives for large-scale recovery efforts. However, Altilium’s advanced methods focus on maximizing lithium and graphite recovery, improving efficiency, and enhancing the economic viability of recycling LFP batteries.

-

Demand for advanced recycling methods

Effectively processing various battery chemistries requires advanced technologies and tailored methods. Without specialized solutions, recovery efficiency drops, limiting sustainability efforts. Overcoming these technical challenges is crucial to leveraging material reuse and ensuring a more efficient, environmentally responsible battery life cycle.

Moving forward

Altilium is making significant strides in battery recycling, reinforcing its role in the UK’s push for a greener, resource-efficient future. Its newly established ACT2 facility in Plymouth can extract valuable materials from an entire EV battery daily, marking an important step toward sustainable resource recovery. However, the company’s ambitions extend far beyond this initial phase.

A large-scale recycling hub is planned for Teesside, designed to process battery waste from more than 150,000 EVs annually. This state-of-the-art facility will enhance the UK’s battery supply chain by supporting a circular economy and minimizing environmental harm. By repurposing critical minerals like lithium and graphite, Altilium is setting new standards for battery recycling.

Beyond waste reduction, Altilium’s recycling initiatives align with growing regulatory requirements for sustainable practices. With stricter environmental policies emerging, the company’s operations ensure compliance while driving innovation in the industry.

As the EV market expands, recycling will be essential to reducing supply chain pressures and securing essential raw materials. By leading these efforts, Altilium is not just addressing waste but actively shaping a cleaner, more resource-efficient future for electric mobility and the broader green economy.

Recycling EV batteries is essential for reducing reliance on mining and minimizing waste. As the UK advances in battery recycling, companies are driving innovation to meet rising demand, ensuring a greener future for transportation and resource management. As one of the Top 20 EMS companies in the world, IMI has over 40 years of experience in providing electronics manufacturing and technology solutions.

As one of the Top 20 EMS companies in the world, IMI has over 40 years of experience in providing electronics manufacturing and technology solutions.

We are ready to support your business on a global scale.

Our proven technical expertise, worldwide reach, and vast experience in high-growth and emerging markets make us the ideal global manufacturing solutions partner.

Let's work together to build our future today.

Other Blog