Silicon Carbide: Powering the Future of EVs

From Tesla to Toyota, top automotive manufacturers are using silicon carbide (SiC) technology in their electric vehicles. Find out why this semiconductor is gaining ground in the power electronics industry and how it may be a key element in a sustainably all-electric automotive future.

Could silicon carbide (SiC) make the world’s streets carbon-free? Many top auto manufacturers are banking on SiC to drive the future of electric vehicles (EVs). Tesla led the pack in 2018, equipping its Model 3 with SiC metal-oxide-semiconductor field-effect transistors (MOSFETs).

Since then, many automobile manufacturers have followed suit. In 2020, Chinese EV company BYD launched Han, an electric luxury sedan with a motor control unit that uses SiC technology. For its second-generation Mirai fuel cell EV, Toyota used silicon carbide semiconductors in the intelligent power model (IPM) transistors.

Last year, Renault entered a partnership with STMicroelectronics, collaborating with the electronics manufacturing company on the design, development, and production of SiC devices. Meanwhile, General Motors has reached a strategic supplier agreement with Wolfspeed. The widegap semiconductor company will develop and supply SiC power devices for the American auto manufacturer’s future EV programs.

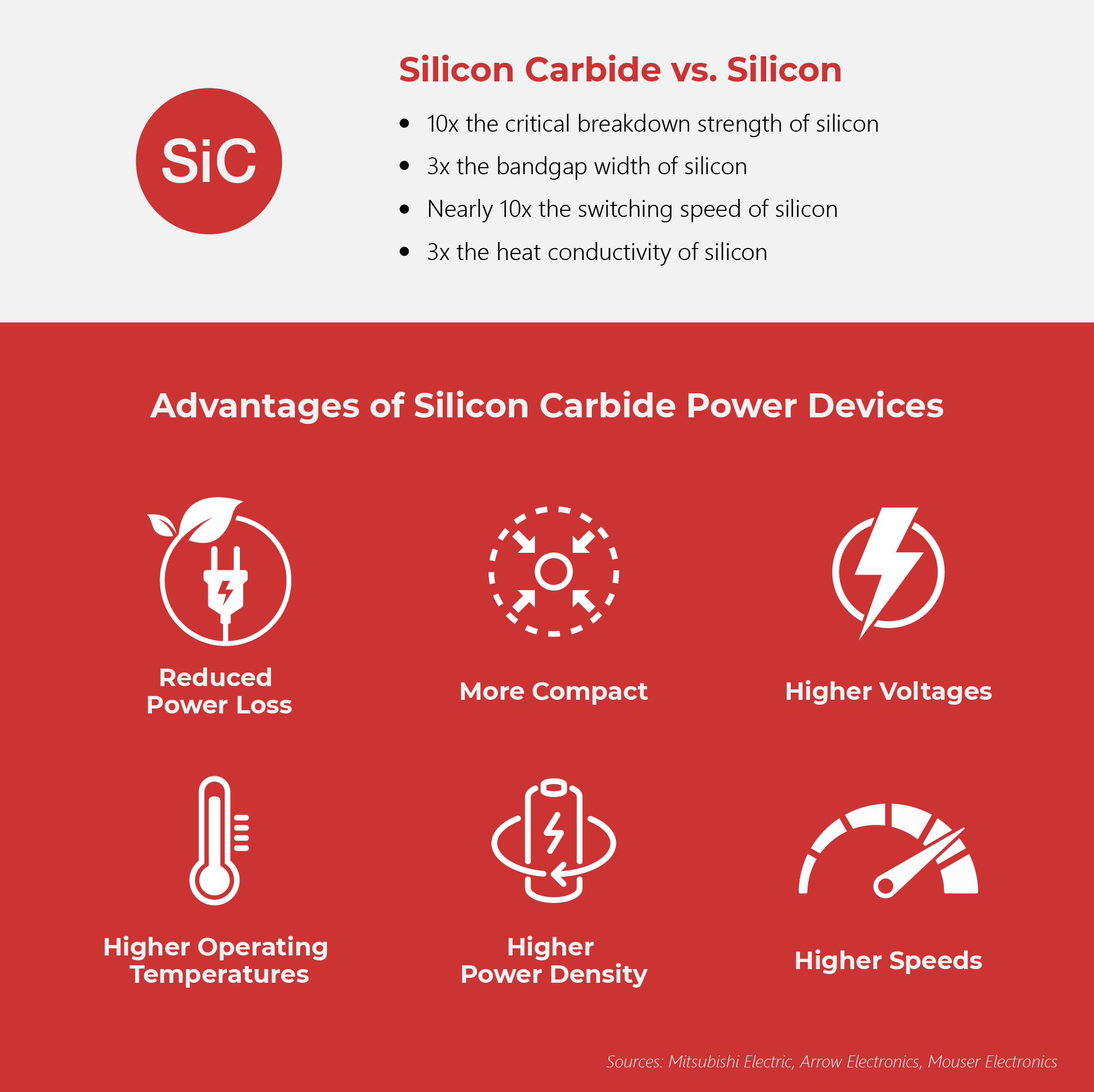

In the race to e-mobility, the range, efficiency, and cost of EVs are major road obstacles. How can silicon carbide lead the way to an all-electric automotive industry? To get a clearer picture, let’s see how silicon carbide stacks up against silicon, which has long dominated the field of power electronics.

(Also read: Plugging into E-Mobility)

Silicon carbide vs. silicon

Given all these characteristics, silicon carbide can operate at higher temperatures, power, and switching frequencies than silicon–all while reducing power losses and increasing efficiency.

Powering an all-electric future

Enhancing the efficiency of EV technology is crucial to an all-electric future, as this will increase the range of EV batteries and shorten charging time while reducing the weight of the vehicle.

(Also read: Innovations in EV Batteries)

Because of its advantages, silicon carbide is gaining mass adoption and being used in various EV systems such as the DC-DC converter, the traction inverter, and the on-board charger.

“High-voltage SiC power devices are also key in enabling the fast-charging infrastructure that will lift the last major barrier in wide EV consumer acceptance,” Victor Veliadis, executive director and CTO for the PowerAmerica Manufacturing USA Institute, told Semiconductor Engineering. “SiC is highly efficient at the high voltages, enabling fast battery charging times that are comparable to filling the tank of conventional vehicles.”

Silicon carbide power electronics are enabling a surge in 800-volt drive systems, paving the way for lighter EVs with greater range. South Korean automotive manufacturer Hyundai was one of the first to commercialize 800v systems for its all-new, dedicated electric vehicle platform.

“We know that charging EVs is stressful for our consumers. So we have applied onto the E-GMP the 800V high-speed charging system, which significantly reduces the charging time relative to BEVs based on ICEV platforms,” Vice President Chung Jin-Hwan, Head of Hyundai’s Electrification Development Group, shared.

“High-speed charging charges the battery up to 80% of capacity within 18 minutes. The Vehicle-to-Load (V2L) feature allows appliances to run on the car’s battery,” he continued. “Finally, we have applied durable and efficient silicon carbide (SiC) power semiconductors to ensure that the high-voltage charging system runs with the equally high-quality drivetrain.”

A growing market for a cleaner, greener world

Investments, acquisitions, strategic partnerships, and long-term supply agreements reflect the power and promise of silicon carbide. According to French market research firm Yole Développement, the silicon carbide market is expected to exceed USD1.5 billion in 2025.

(Also read: Carbon-Free Roads: Will Nations Hit Their Targets?)

The global push to reduce carbon emissions, government incentives to promote e-mobility, and greater involvement from the automotive industry are driving us toward a cleaner and greener future. As we combat climate change and its devastating impact, silicon carbide could get us back on the right track.

As one of the Top 21 EMS companies in the world, IMI has over 40 years of experience in providing electronics manufacturing and technology solutions.

We are ready to support your business on a global scale.

Our proven technical expertise, worldwide reach, and vast experience in high-growth and emerging markets make us the ideal global manufacturing solutions partner.

Let's work together to build our future today.

Other Blog