Enhancing Automotive Vision: IMI's Advanced Camera Manufacturing Capabilities

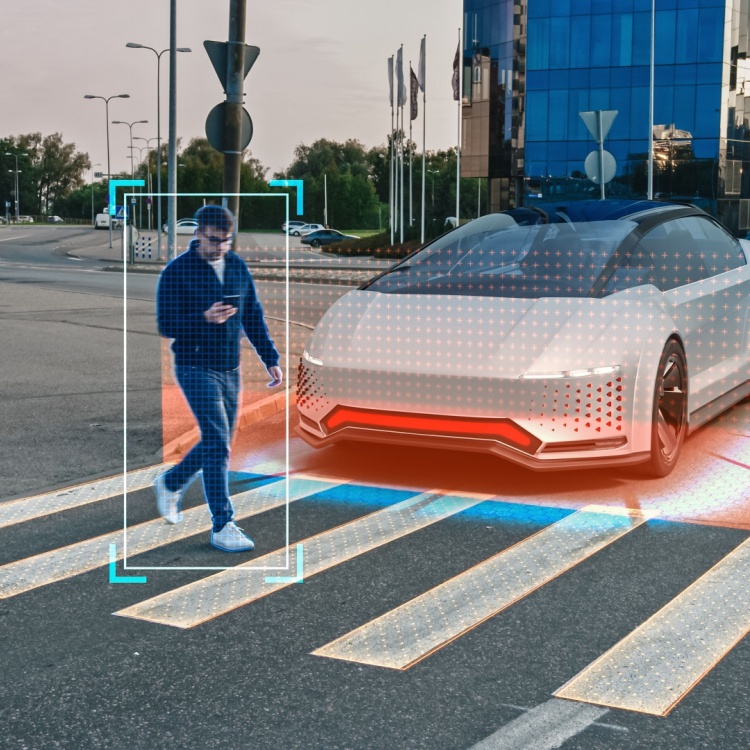

In today’s technology-driven world, vision-based systems play a crucial role in ensuring safety, efficiency, and convenience across multiple applications, particularly in automotive driving systems.

However, environmental challenges, particularly extreme weather conditions, can hinder the functionality of these systems. Ensuring the reliability of vision technology in the automotive market is crucial, where real-time visibility can prevent accidents and enhance overall driving experiences.

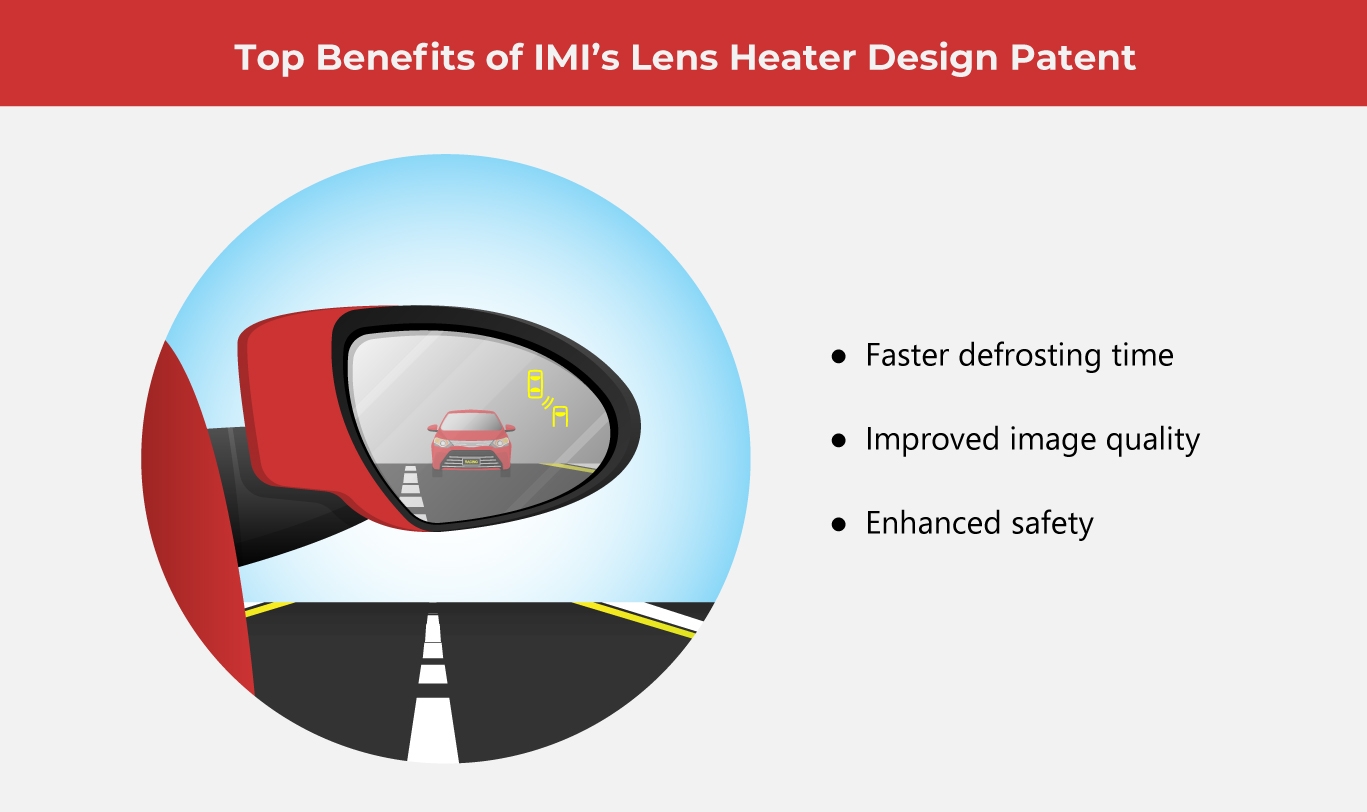

One of IMI’s notable advancements in this domain is its patented Lens Heater Design (US11086092B2), an innovative solution aimed at addressing the challenges posed by cold weather on exterior-mounted cameras.

IMI's Expertise in Camera Manufacturing

Automotive cameras have become indispensable in modern vehicles, enhancing safety, driver awareness, and overall functionality. With the rise of advanced driver-assistance systems (ADAS) and autonomous driving technologies, high-quality imaging solutions are essential for enabling features such as lane departure warnings, blind spot detection, and parking assistance.

Lidar receiver modules play a vital role in automotive sensing systems by providing accurate depth perception and object detection capabilities. Unlike traditional cameras that rely on visible light, lidar technology emits laser pulses to measure distances, creating a precise 3D map of the environment. By integrating lidar receiver modules, vehicles can achieve superior situational awareness, enabling safer navigation and improved real-time decisions.

IMI has established itself as a leader in the development and production of automotive cameras and lidar receiver modules, leveraging decades of experience in electronics manufacturing. With a strong foundation in engineering, design, and production, IMI delivers high-performance solutions tailored to meet the stringent requirements of the automotive industry.

A key factor that sets IMI apart is its proficiency in the chip-on-board (COB) process, which enhances camera performance by allowing the integration of bare die sensors. Unlike traditional cameras that utilize packaged sensors, COB technology enables direct mounting of the sensor onto the circuit board, minimizing signal loss and enhancing thermal management.

Why the US11086092B2 – Lens Heater Design Patent is unique

Cold temperatures, moisture in the air can settle on the camera lens, forming frost or ice that blocks the sensor’s view. Additionally, sudden shifts in temperature—such as transitioning from a warm garage to a freezing outdoor environment—can cause condensation to form on the lens, further reducing visibility. Traditional defogging methods, such as passive heating from engine components or airflow from the vehicle’s heating system, are often insufficient or slow to take effect.

At the core of this innovation is a specialized lens heater system that directly addresses visibility issues caused by ice and moisture accumulation. The system works by actively heating the first glass element of the camera lens, ensuring that frost and condensation are quickly dissipated.

By focusing on the outermost glass component, the heating mechanism prevents moisture from settling and refreezing on the lens, allowing for uninterrupted operation. This targeted heating approach not only improves visibility but also extends the lifespan of the camera by reducing the strain caused by frequent exposure to harsh weather.

Advantages of IMI’s lens heater patent

The lens heater system described in US11086092B2 offers several advantages:

-

Faster defrosting time

Unlike usual methods that rely on ambient temperature changes or airflow from the vehicle’s heating system, the integrated heating element directly warms the camera's first glass element. This targeted approach accelerates the defrosting process, preventing prolonged obstructions that could compromise the vehicle’s safety systems. By melting ice and dissipating condensation quickly, the lens heater ensures that the camera remains fully operational even in freezing conditions, reducing downtime and improving the reliability of vision-based driving assistance features.

-

Improved image quality

A clear camera lens is essential for maintaining high-quality imaging, especially in applications that require real-time object detection and recognition. Frost, condensation, and ice buildup can distort images, obscure crucial details, and interfere with the accuracy of ADAS. The lens heater system eliminates these issues by actively preventing moisture accumulation on the lens surface. This results in consistently sharp and precise images, allowing the vehicle’s vision systems to function optimally in all weather conditions.

-

Enhanced safety

Safety is a critical concern in modern automotive design, particularly as vehicles become increasingly autonomous and dependent on vision-based technologies. Any obstruction in the camera’s field of view can lead to delayed responses or inaccurate detections, increasing the risk of accidents. Drivers and autonomous systems can rely on consistent, high-quality visual input, leading to better decision-making and improved accident prevention measures.

Focusing on the future

IMI envisions a future where automotive camera technology evolves to become an indispensable component of vehicle safety, particularly in the era of autonomous driving.

As automation and driver-assistance systems become more sophisticated, the need for reliable, high-performance vision technology has never been greater. IMI remains at the forefront of this transformation, continuously exploring new ways to enhance camera functionality and adaptability in diverse driving conditions. Through research and development, the company is pushing the boundaries of innovation to create imaging solutions that improve road safety and driving efficiency.

IMI continues to shape the future of automotive vision technology. Through collaboration with global industry leaders and a deep focus on continuous improvement, the company is not only advancing the capabilities of automotive cameras but also setting new standards for reliability, durability, and functionality.

As one of the Top 20 EMS companies in the world, IMI has over 40 years of experience in providing electronics manufacturing and technology solutions.

We are ready to support your business on a global scale.

Our proven technical expertise, worldwide reach, and vast experience in high-growth and emerging markets make us the ideal global manufacturing solutions partner.

Let's work together to build our future today.

Other Blog