New Challenges for the Supply Chain

After the pandemic, business and industry leaders have shifted into a mindset that puts resilience above all else. What challenges resilience for the global supply chain, and how can technology help?

As global trade finds itself catching its breath from the challenges of dealing with the aftermath of a pandemic, these challenges continually evolve as new ones emerge. According to logistics and supply chain titan Maersk, these three challenges are shaping up to be formidable obstacles this year:

- A slowdown in global trade growth from 6% in 2020 and 3.2 in 2021 to 2.7% in 2023 (as per data from the IMF)

- The OECD reports a shortage of skilled workers.

- Energy rates continue to skyrocket. The World Bank says that these rates will continue to be 50% above their five-year average until 2024

Apart from these three emerging challenges are the twenty-first-century constants of climate-related problems and escalating geopolitical developments. Experts say that industries must find a way to work within these conditions and can no longer use these as an excuse for bottlenecks and shortages.

Resilience is a big buzzword in global trade because of this, and many business leaders have pivoted to keep up with the ever-changing, ever-shifting demands in the supply chain. At the beginning of the year, several experts weighed in on trends just beginning to emerge in the supply chain, but as we move further into the current year, expectations from both ends of the chain have scaled up.

(Also read: Experts Weigh In On Supply Chain Trends)

Bolstering Resilience in the Digital Age

To address these urgent challenges, businesses can look into bolstering resilience by looking into big-picture solutions.

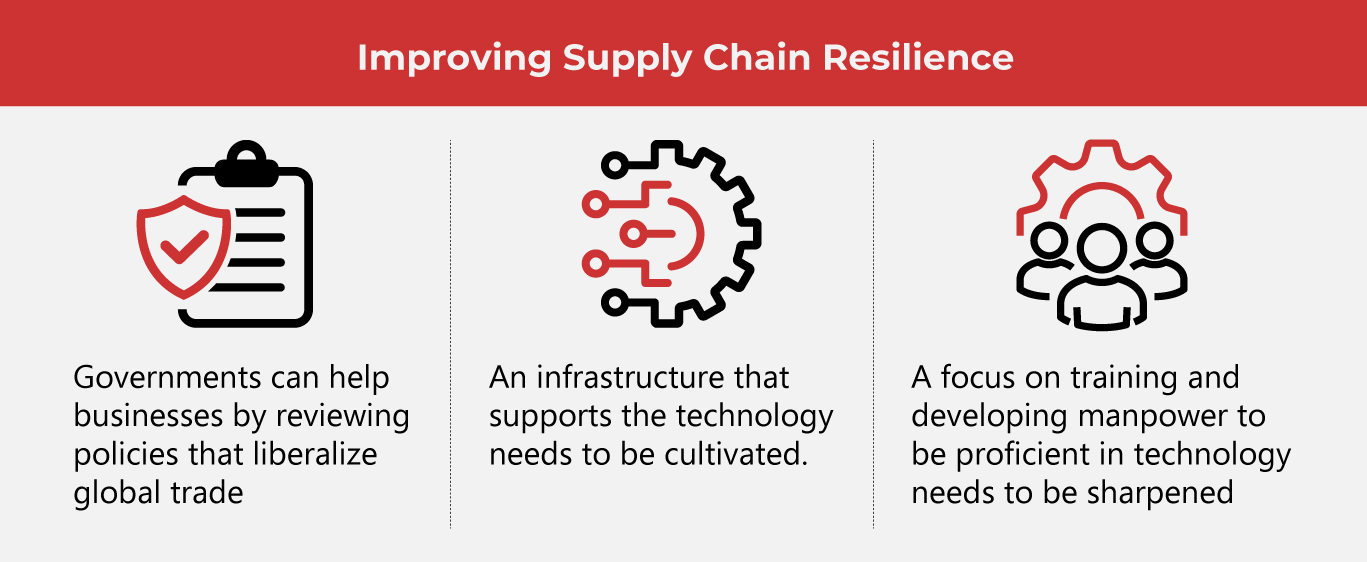

First, businesses need plenty of help from governments. The World Economic Forum says that “governments need to avoid protectionist policies and work together” with businesses to “increase economic cooperation and liberalize global trade”. Diplomacy must work to support businesses and create a free and transparent dialogue between parties, identify choke points that stimulate bottlenecks, delays, and shortages, and draft policies that protect and stimulate these businesses.

Part of the support that industries need is the infrastructure for technology and innovations. There’s no shortage of innovations that emerge for industries, but what can hinder these from being properly implemented and maximized is infrastructure. Without appropriate infrastructure, innovations are as good as ideas drafted on a drawing board. Industries need the infrastructure to keep up with the technology that will help them. Modernizing trade infrastructure is vital.

A good example of this can be found in many logistics companies. While we see robots and wearable technology on the floors of warehouses, the logistics side of things seems to be staunchly stuck in the paperwork of it all. Many of these businesses still do rely heavily on outdated analog systems. This can cause risks and blind spots related to locating cargo.

What some logistics companies such as DP World are looking into doing now to revitalize and possibly revolutionize their business is to find a way to “do for logistics what Amazon has done for e-commerce”. Other logistics companies need to adopt the same mindset to move forward into the digital age.

“Boosting digital accountability” involves a broad adoption of digital systems and an integration of digital solutions into the global trade ecosystem. Traditional or analog systems may not be completely done away with for practical reasons, but there must be a way for digital solutions to take the lead and be able to work with existing systems.

Forbes.com says that “technologies like AI, robotics, and automation are valuable tools…but only when applied for measurable business results.” This statement is related to the big digital accountability challenge posed to many businesses today.

Learning how to leverage data and technology can help businesses predict stumble blocks, prepare for disruptions, and bolster logistics.

Along with the infrastructure, the technology, and the tools to make this happen are the skills that workers bring to the table. The OECD reports that there is a shortage of raw materials and skiled workers. A focus on training, developing, hiring, and retaining skilled manpower should be sharpened. Retention is an important piece of the pie, as it becomes clear that there may not be a shortage of skilled workers if there is a stable and desirable retention program for those who qualify.

While experts say that disruptions in the supply chain are expected to continue this year, there are many lessons from previous years global industry leaders can take from and use to face challenges old and emerging. Some of the insights discussed above are simply scratching the surface, but as the year moves forward inevitably into the uncertain future, the rest of the world can only wait and see if our leaders are all up to the task.

As one of the Top 19 EMS companies in the world, IMI has over 40 years of experience in providing electronics manufacturing and technology solutions.

We are ready to support your business on a global scale.

Our proven technical expertise, worldwide reach, and vast experience in high-growth and emerging markets make us the ideal global manufacturing solutions partner.

Let's work together to build our future today.

Other Blog