Need to Test LED Strips? Here Are 10 Effective Ways

Manufacturers rely on accelerated LED-strip testing as a key tool for product validation, subjecting lights to controlled stress conditions that mimic years of use in just a fraction of the time. By fast-tracking performance insights, engineers can spot potential weaknesses early, assess durability, and refine designs before products reach the market.

Light-emitting diode (LED) strips, often referred to as tape or ribbon lights, are flexible circuit boards lined with surface-mount device (SMD) LEDs and typically backed with adhesive for easy installation. Available in single-color, red-green-blue (RGB), or addressable options, these versatile lights inspire designers with limitless linear lighting possibilities, making them a future-ready choice for modern spaces.

These lighting solutions are widely used in homes, commercial spaces, and creative projects. Their flexibility, efficiency, and smart-control features have boosted demand, making them a notable contributor to electronic exports.

Because of their energy efficiency and aesthetic adaptability, LED strips are driving strong demand. The rising adoption of sustainable, green lighting solutions is also fueling the global LED strip market, which is expected to nearly double from US$1.28 billion in 2024 to US$2.98 billion by 2030, at a 15.1% CAGR.

However, quality control plays a vital role in shaping the product life profile of LED strips. A failure after installation can be costly and difficult to fix, especially when the strip is built into a custom fixture. Rigorous testing ensures reliability upfront, extending lifespan and reducing the risk of premature breakdowns.

(Also read: Top Tech Tools to Take Your Manufacturing to the Next Level)

Testing LED strips? Try these 10 procedures

When it comes to evaluating performance, LED strips benefit from proven testing solutions that help verify quality before they’re put to use.

- Power efficiency test

As part of an ongoing reliability test, engineers examine whether LED strips deliver the power performance promised on paper. For low-voltage models, a DC supply and multimeter help track current and voltage, with power calculated using the standard P = UI formula. High-voltage strips are assessed with an electronic power meter, which captures both consumption and power factor. With these steps, testers confirm efficiency and ensure the strips align with design expectations.

- Light performance evaluation

To evaluate luminous efficiency, engineers run detailed optical tests that look beyond simple brightness. Using tools such as photometers or integrating sphere systems, they measure total light output while checking for consistency in color rendering index, color temperature, and tolerance levels. For example, warm light at 3000 Kelvin (K) or cool light at 6000K should maintain a color rendering index of at least 80 and a Standard Deviation of Color Matching within three steps.

- Adhesion strength test

To gauge how well LED strip adhesives hold up, engineers run both real-world and laboratory testing. In the lab, steel plates and a tack tester apply a steady weight for hours to see if the bond stays intact. Beyond that, strips are mounted on common surfaces like wood and metal to mimic daily use. Even under full power for days, the adhesive should resist peeling, with long-term checks continuing for years to confirm durability.

- Durability test

LED strips are subjected to durability tests that replicate everyday use and installation conditions. Engineers check tensile strength at solder points, then put strips through repeated rolling, swinging, and twisting cycles to see if components stay firmly in place. Vibration tests simulate the bumps and jolts of transport, while hot and cold conditions reveal how strips hold up under different environments. The goal is simple: ensure every strip remains intact throughout its lifespan.

- Thermal shock test

LED strips undergo thermal cycling tests in extreme temperatures. Inside climate chambers, strips are cycled between cold and high heat, sometimes pushed from –40°C to +85°C in repeated shock rounds. They are also kept running for days in sub-zero and hot conditions to check for failures. After returning to room temperature, each strip is inspected to ensure its appearance, adhesion, and performance remain unchanged, confirming stability even under the harshest environments.

- Water resistance test

Exposure to harsh conditions is a crucial part of waterproof testing for LED strips. The Salt Spray Test exposes products to a fine saline mist to replicate corrosive marine or industrial environments, helping assess corrosion resistance and coating durability. The Freeze Spray Test rapidly cools components, revealing weaknesses in adhesives or materials under sudden cold stress. By replicating these demanding scenarios, engineers can spot frailties and strengthen designs, and confirm product consistency.

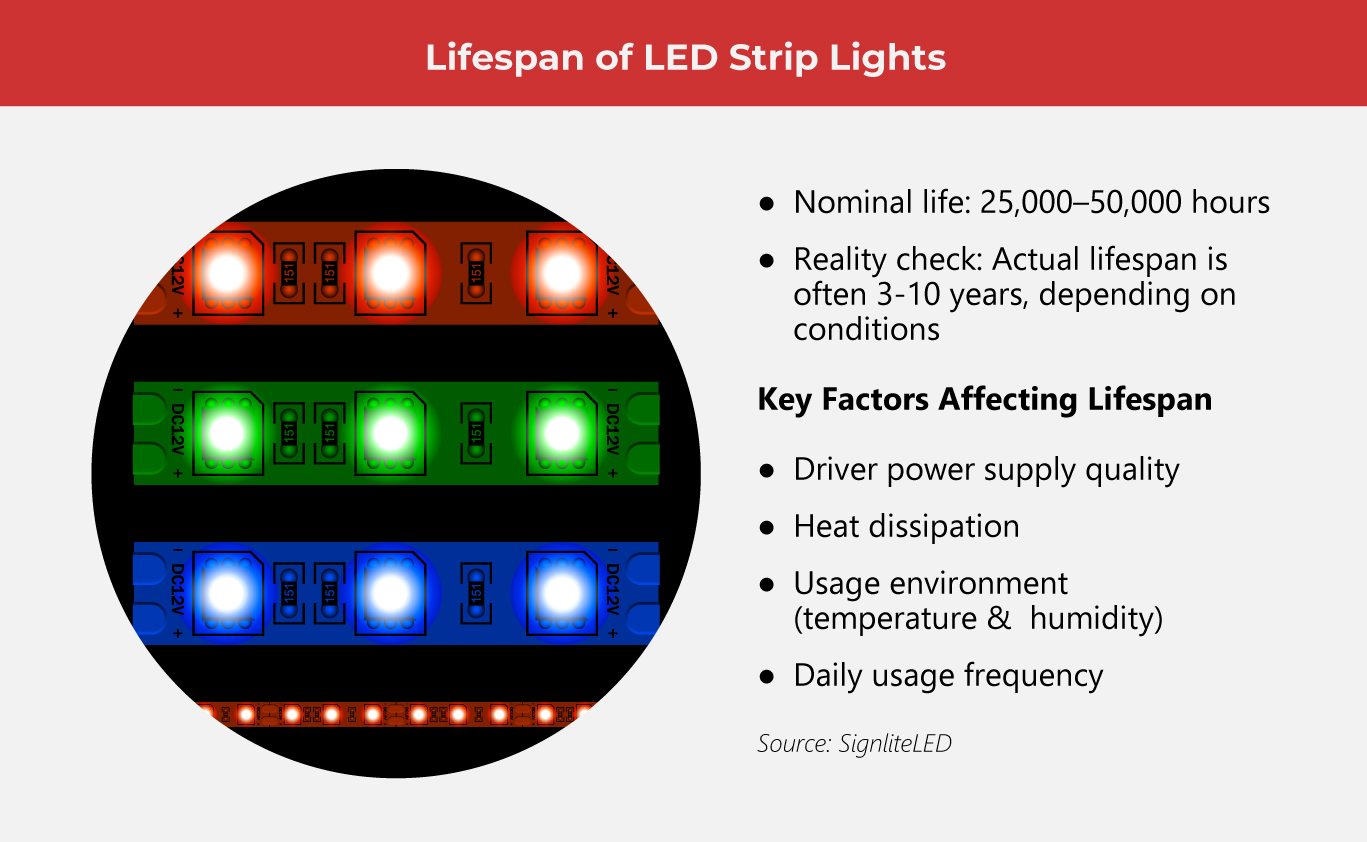

- Longevity test

To assess how LED strips hold up over time, engineers use a mix of life cycle and accelerated tests. Samples are first run at room temperature, with brightness, power, and color checked regularly to track gradual decline until output drops to 70%. In harsher trials, strips operate nonstop in heat and humidity to mimic years of wear in just weeks, with output required to stay above 85%. Additional ultraviolet exposure tests verify durability.

- Mechanical test

LED strips undergo rigorous mechanical evaluations to mimic real-world handling stresses. Engineers subject samples to repeated bending and folding to assess flexibility and solder-joint durability. Vibration testing, which employs industry-standard protocols such as IEC 60068-2-6, ensures resistance to mechanical oscillation and impacts. These checks help confirm that LED strip components remain securely intact under continuous flexing and vibration, reinforcing their reliability in everyday use.

- Electromagnetic compatibility test

Such testing confirms that LED strips operate smoothly without causing interference to surrounding electronic devices. First, Electromagnetic Interference (EMI) testing checks that LEDs don’t disrupt nearby devices, using standards like CISPR 15 for radiated and conducted emissions. Next, anti-interference (immunity) testing verifies that strips remain stable even when exposed to external electromagnetic disturbances, following protocols for field immunity. These steps confirm that lighting systems perform reliably without causing or succumbing to electromagnetic noise.

- Environmental test

Environmental compliance testing ensures LED strips meet global safety and sustainability benchmarks. Key checks include verifying adherence to the Restriction of Hazardous Substances (RoHS) Directive and the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation, which limit hazardous materials such as lead, mercury, and cadmium in electronic products. By screening materials for harmful chemicals, these tests safeguard both consumers and the environment. Test items may vary depending on the LED type and use.

(Also read: How Customized Test Solutions Reduce Cost, Improve Quality)

Quality testing ensures LED strips meet high standards, but the process should not end there. Manufacturers must repeat tests whenever materials or components change to guarantee consistent performance. Users also play a role: mishandling during unboxing, cutting, or mounting often causes damage. With responsible production and careful use, LED strips can deliver long-lasting, worry-free lighting that enhances everyday spaces with both reliability and brilliance.

As one of the Top 20 EMS companies in the world, IMI has over 40 years of experience in providing electronics manufacturing and technology solutions.

We are ready to support your business on a global scale.

Our proven technical expertise, worldwide reach, and vast experience in high-growth and emerging markets make us the ideal global manufacturing solutions partner.

Let's work together to build our future today.

Other Blog