Top 15 Benefits of Using IIot

IIoT connects smart sensors, machines, and other tools to enhance manufacturing capabilities by enabling real-time data sharing, reducing downtime, and improving decision-making. While IoT powers everyday devices, IIoT applies this connectivity to large-scale manufacturing, offering greater efficiency and higher returns. As the industry shifts from automation in Industry 4.0 to a more human-centered Industry 5.0, IIoT plays a key role in advancing production strategy.

IIoT or smart manufacturing leverages Big Data to enhance decision-making, requiring manufacturers to adopt digital transformation. Four key pillars support effective industrial manufacturing solutions driven by IIoT:

- Sophisticated machinery with sensors and software that can monitor and record data

- Scalable cloud computing systems that enable system integration by storing and processing data

- Advanced analytics systems that drive manufacturing excellence by interpreting data to optimize operations

- Skilled employees who apply data-driven insights to maintain efficiency

Manufacturing is rapidly digitizing, with IoT adoption accelerating. The market, valued at $62.1 billion in 2021, is projected to reach $200.3 billion by 2030, growing at a 13.9% annual rate.

15 Ways IIoT Boosts Factory Efficiency

Integrating IoT into industrial automation offers numerous advantages that can transform global manufacturing processes.

-

Resource management

IoT sensors provide real-time insights, improving productivity in the industrial market. For instance, a beverage company reduced water consumption by 11% with an IoT-based system. IIoT enables automation and remote monitoring, helping manufacturers maximize output.

-

Process simulation

Digital twins allow teams to analyze data and minimize interruptions. By simulating processes, engineers can conduct product testing and identify issues without risking physical assets. This technology offers insights into the overall manufacturing process, helping pinpoint bottlenecks.

-

Predictive maintenance

With IoT, manufacturers move from reactive to proactive maintenance. By continuously monitoring machinery performance, manufacturers can anticipate issues, schedule maintenance, and ensure production continuity. This approach provides significant economic value by minimizing unplanned expenses and boosting equipment lifespan.

-

Site safety

ID badges, proximity sensors, and wearable devices enhance safety in manufacturing markets by reducing workplace accidents and monitoring employee location. Integrated safety systems alert management to accidents, enabling immediate intervention and generating data to prevent future incidents.

-

Quality assurance

IoT sensors detect workflow anomalies, adjust environmental fluctuations, and monitor post-production conditions. This reduces manufacturing deviations by over 65%, preventing costly product recalls and boosting customer satisfaction. Precision machinery, automation, and digitization ensure more accurate production.

IoT makes real-time inventory tracking, optimizing storage, and automating processes possible. Sensors and RFID tags provide accurate stock visibility and streamline order fulfillment. By minimizing stockouts or overstocking, manufacturers enjoy better overall operational productivity.

-

Supply chain management

Real-time insights improve factory processes by offering up-to-date customer demand signals, reducing dependence on outdated forecasting and historical trends. With 80% of industry leaders seeking better connectivity and visibility, IoT optimizes supply chain operations and responsiveness.

-

Savings

System development through IIoT solutions allows manufacturers to leverage data-driven insights to cut costs and increase revenue. By automating processes and enabling predictive maintenance, it reduces labor costs, improves efficiency, and supports remote monitoring, driving growth.

-

Better accuracy

Human error is significantly reduced with the help of IIoT, as it automates and digitizes manufacturing processes. By incorporating AI and machine learning, IIoT minimizes the risk of operational mistakes, enhancing engineering capabilities and securing critical data.

-

Production line efficiency

IIoT enables standardization across production lines, allowing manufacturers to assess factors like machine capabilities and capacity across multiple plants. This helps improve product qualification by identifying the most efficient production sites and enabling operational capabilities across locations.

-

Faster product launch

Leveraging IIoT in product development enhances efficiency by providing instant data. With optimized processes and predictive maintenance, manufacturers can quickly identify issues, reduce delays, and accelerate time-to-market, resulting in faster product launches and faster return on investments (ROI).

-

Reduced downtime

Machine downtimes, affecting 82% of companies, contribute to $50 billion in annual losses. IIoT applications monitor equipment, allowing design and engineering teams to predict and prevent failures, reducing disruptions, and enhancing productivity.

-

Sustainability

By enabling continuous monitoring of energy usage, waste production, and resource consumption, manufacturers can optimize processes and enhance energy efficiency. This data-driven approach reduces waste, improves sustainability, and supports eco-friendly practices, ultimately minimizing environmental impact and supporting net-zero goals.

-

Scalability

Automated systems offer flexibility, allowing manufacturers to quickly adjust to changing production demands or market shifts. Unlike traditional methods, automation ensures efficient adaptation to product diversification, helping maintain competitiveness and aligning with business needs, including product life profile adjustments.

-

Employee retention

By integrating IoT solutions, manufacturers create safer and more efficient workplaces. Real-time monitoring, predictive maintenance, and wearable devices reduce physical strain and safety risks, fostering a comfortable work environment that improves employee satisfaction, leading to higher retention and reduced turnover.

Hurdles in implementing IIoT

A key approach to understanding IoT implementation challenges is examining the specific areas where manufacturers have encountered obstacles.

-

High start-up costs

With IIot, manufacturers invest in costly technology integration. However, long-term savings can be achieved through improved efficiency and reduced downtime, ultimately leading to lower operational costs over time.

-

Choosing the right devices

Selecting the appropriate devices for data collection is critical in IoT implementation. Manufacturers must decide whether to invest in new devices or upgrade existing ones with sensors. While this may seem straightforward, logistical and budgetary constraints can complicate the process.

-

Data collection

The complexities of defining data types, ensuring compatibility with existing systems, and maintaining secure, reliable connections can create roadblocks, especially when devices lack power or electronic infrastructure.

-

Data overload

Manufacturers struggle to filter important information and use it to drive improvements. The key question becomes: How can you leverage data to offer new value to customers?

-

Security & privacy threats

The integration of devices increases the exposure to potential cyber threats and breaches. Ensuring secure data transmission and protecting sensitive information are critical obstacles for manufacturers.

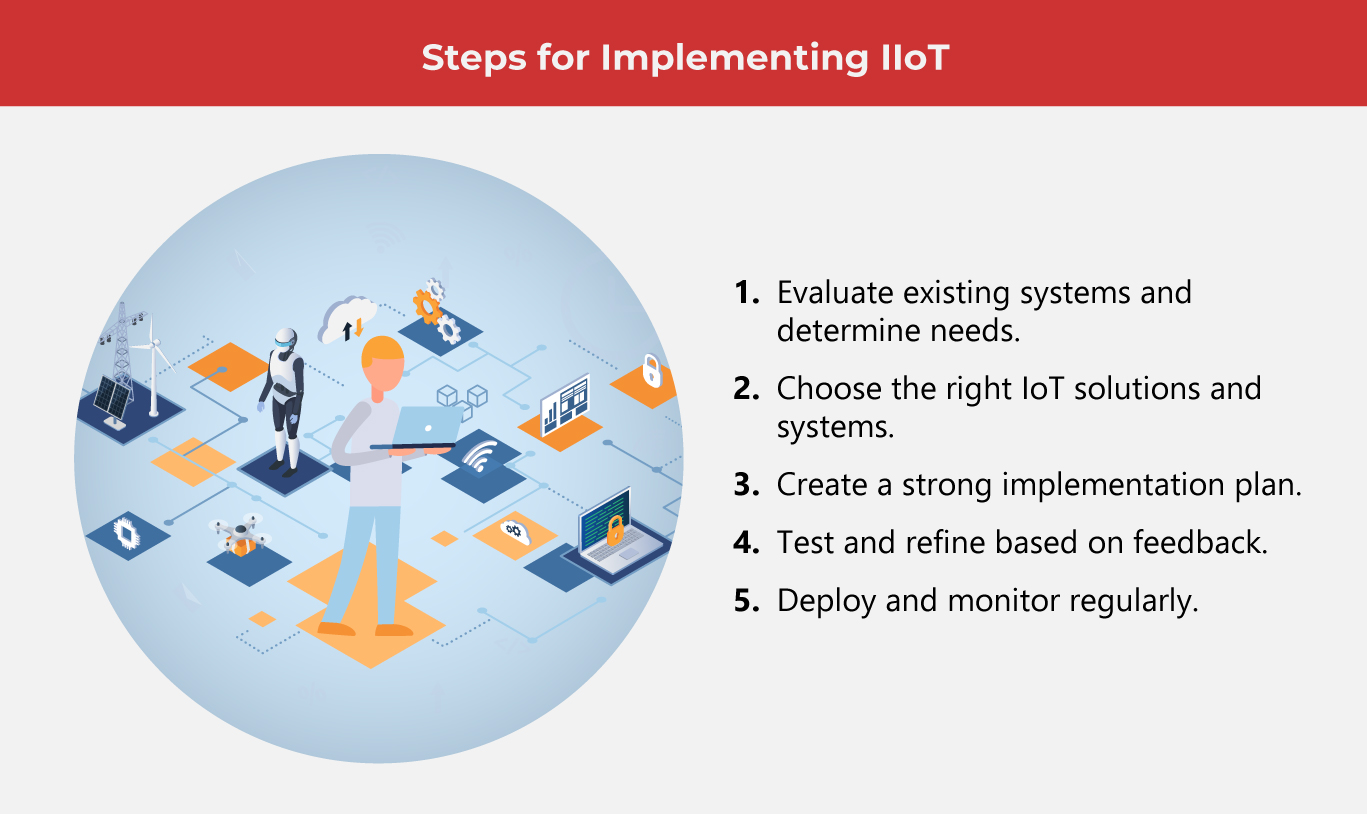

Implementing IIoT in factories can significantly enhance productivity, efficiency, and safety. While the journey may present challenges, with the right strategy, tools, and ongoing adjustments, businesses can fully leverage IIoT's potential. Continuous monitoring and adaptation ensure long-term success in transforming factory operations.

Implementing IIoT in factories can significantly enhance productivity, efficiency, and safety. While the journey may present challenges, with the right strategy, tools, and ongoing adjustments, businesses can fully leverage IIoT's potential. Continuous monitoring and adaptation ensure long-term success in transforming factory operations.

As one of the Top 20 EMS companies in the world, IMI has over 40 years of experience in providing electronics manufacturing and technology solutions.

We are ready to support your business on a global scale.

Our proven technical expertise, worldwide reach, and vast experience in high-growth and emerging markets make us the ideal global manufacturing solutions partner.

Let's work together to build our future today.

Other Blog