The Rise of Microturbines for Drones

The global aerospace microturbine market is poised for strong growth, rising from US$49.48 million in 2024 to an estimated US$117.56 million by 2034, driven by increasing demand for efficient distributed power generation technologies.

Microturbines are small gas turbines that generate power from a few to several hundred kilowatts and are increasingly finding applications in the automotive market. Used in vehicle turbochargers, auxiliary aircraft power units, and small jet engines, these systems combine compressors, combustors, and generators to provide efficient and reliable power in a compact form.

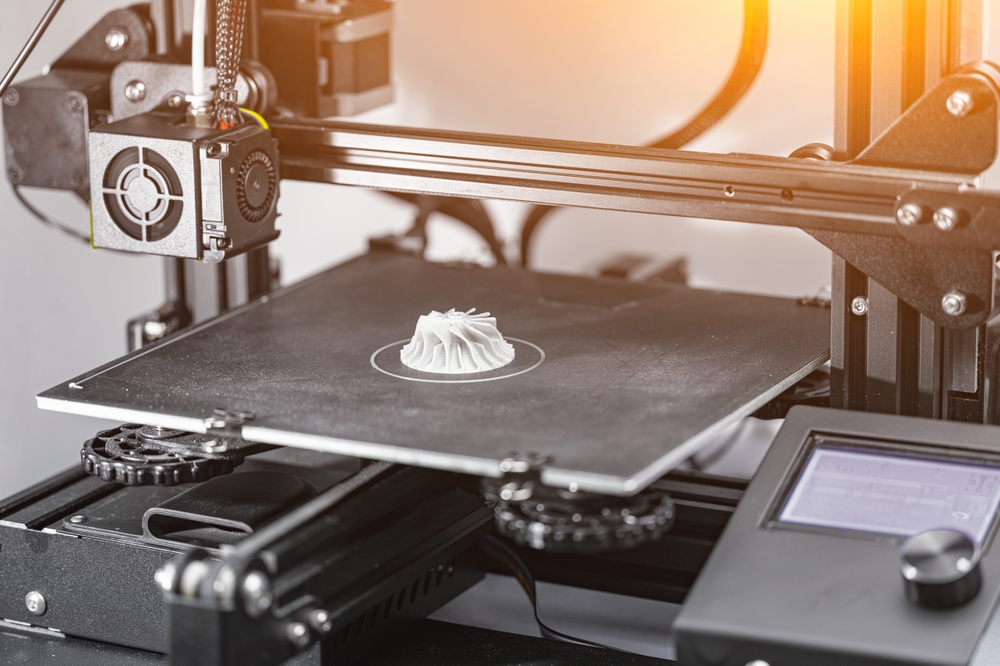

These turbines are becoming key manufacturing solutions in defense and drone technology, delivering lightweight yet high-performance power. Advances in 3D printing have revolutionized their production, slashing part counts while boosting fuel efficiency and power density. As demand surges for larger drones and missile systems, innovation in scalable microturbine design is gaining momentum.

Often built from titanium, aluminum, and stainless-steel alloys, microturbines deliver operational efficiency of 25% to 35% while running on diesel or natural gas. Their quiet performance, clean emissions, and emphasis on sustainability make them a practical choice for commercial base load and cogeneration power systems.

In terms of additive manufacturing, microturbines are proving to be a promising innovation for aerospace propulsion. Their potential to power high-speed, long-range unmanned aerial system (UAS) platforms highlights the technology’s effectiveness and scalability. Additive processes enhance performance and support advancements in thermal analysis and antenna design.

(Also read: Hydra Drones: UK’s New Line of Defense)

A look at its pros and cons

The aircraft microturbine market has become a key force in modern aerospace, advancing efficiency and performance through design for manufacturing principles. These compact engines enhance endurance and stealth while offering powerful, cost-effective energy solutions. With adaptable designs, microturbines are gaining traction across commercial and domestic applications.

However, extreme operating temperatures remain a critical focus in the aircraft microturbine market’s reliability testing. With heat levels reaching up to 1600 Kelvin, efficiency can drop as air density decreases and turbine blades risk cracking. To maintain durability and performance, air or magnetic bearings are preferred over traditional oil-based systems.

Nevertheless, opportunities in the renewable energy market are expanding with the advancement of hybrid power technology. By integrating multiple fuel sources and energy storage systems, this innovation boosts reliability, reduces investment risks, and boosts cost savings. In aviation, it enables better energy management and lowers fuel consumption by roughly 5% compared to standard flights.

Getting to know the A300

An Oxford-based startup, Argive, is helping push the boundaries of design and engineering with its 3D-printed microturbine, the A300. This next-generation gas microturbine is being integrated into MGI Engineering’s SkyShark drone to enhance its independent propulsion system.

The technology is particularly valuable for the SkyShark’s role in intelligence, surveillance, reconnaissance (ISR), strike, and decoy missions, especially in GPS-denied or heavily contested environments where reliable performance and adaptability are critical.

Its standout features include the following:

- Fewer components

Developed through advanced additive manufacturing, Argive’s A300 has a 3D-printed design that cuts component count by four, resulting in a low-maintenance power system. Tailored for high-performance drones like the SkyShark, the A300 delivers exceptional fuel economy and adaptability, making it ideal for missions where weight, endurance, and reliability are paramount.

- Lighter build

The A300 microturbine is crafted using Alloyed’s proprietary nickel superalloy, ABD®-900AM, designed for superior strength and thermal resilience. This advanced material enables the creation of intricate, high-temperature components that are both durable and lightweight. The result is an engine with enhanced heat tolerance, improved performance, and a streamlined design that supports demanding aerospace and drone applications.

- Better economic value

According to Rob Joles, Commercial Director at Argive, the A300 demonstrates how additive manufacturing can dramatically lower production costs. This technology eliminates many assembly steps, consolidates multiple parts into single printed components, and shortens development time. This streamlined approach not only cuts expenses but also enhances reliability and competence—key advantages for high-performance drone systems.

- Speed and consistent performance

MGI Engineering, a UK-based leader in drone and autonomous vehicle technologies, brings deep expertise from motorsport, Formula 1, and aerospace to its cutting-edge designs. According to CEO Mike Gascoyne, integrating Argive’s A300 microturbine into the SkyShark drone represents a breakthrough in performance and capability.

- Boosted supply chain management

Implementing a nearshoring strategy for ancillary component production helps minimize supply chain risks and strengthen operational resilience. By moving manufacturing and sourcing closer to core markets, companies gain tighter control over logistics, quality, and lead times. This localized approach reduces dependency on distant suppliers, mitigates global disruption risks, and ensures a more stable, responsive production network.

(Also read: How 3D Printing Helps Aerospace Take Off)

Additive manufacturing in aerospace and defense engines

China recently successfully tested a fully 3D-printed turbojet engine developed by the Aero Engine Corporation of China (AECC). Designed using advanced digital modeling and topology optimization, the 160-kilogram-thrust engine achieved flight readiness at 4,000 meters while maintaining strength and reduced weight. However, large-scale production remains challenging due to high-temperature material consistency, quality assurance, and certification hurdles.

Meanwhile, US-based Cummings Aerospace has showcased its Hellhound S3 unmanned system. Tested during the Army Expeditionary Warrior Experiment 2025, the 3D-printed, turbojet-powered drone completed a successful GPS-guided mission, proving its modular payload design and operational agility. Developed under the Pentagon’s LASSO program, the S3 highlights how 3D printing is transforming mission-ready systems with faster production, lower costs, and streamlined logistics.

A 3D-printed microturbine could accelerate production and improve the performance of missiles and drones, offering lighter, more adaptable propulsion. High-demand systems such as Kongsberg’s Naval Strike Missile, which costs around $2.1 million and is used by the US Navy and several NATO allies, highlight the need for versatile, easily launched weapons.

Microturbines are also increasingly used in RC planes, long-range drones, and interceptor systems

AI transforming microturbine technology

Artificial intelligence (AI) is reshaping the aircraft microturbine market by enhancing performance monitoring and predictive maintenance. By creating databases of full-load operations, AI trains artificial neural networks to forecast component health and detect faults across varying operating conditions.

Increasingly, AI is replacing human judgment in aerodynamics, supporting the design, validation, and upkeep of compressors and turbines, and enabling more efficient, reliable, and data-driven turbomachinery management.

As one of the Top 20 EMS companies in the world, IMI has over 40 years of experience in providing electronics manufacturing and technology solutions.

We are ready to support your business on a global scale.

Our proven technical expertise, worldwide reach, and vast experience in high-growth and emerging markets make us the ideal global manufacturing solutions partner.

Let's work together to build our future today.

Other Blog