Sodium-Ion Batteries Will Gain Ground This 2026

Talk of sodium-ion batteries has intensified over the past few years, fueled by claims of technical progress and fresh prototypes. Yet beneath the optimism, the path to large-scale adoption remains uneven. Performance gaps with lithium-ion technology persist, even as interest grows across the industrial market in alternatives that could support a more diversified, future-ready energy landscape.

Sodium’s appeal lies in its abundance, but that advantage has yet to translate into a decisive edge. Lithium-ion batteries still outperform sodium-ion on key metrics, and the economics have shifted further in lithium’s favor after lithium carbonate prices fell by more than 70% in recent years. That price collapse has weakened the commercial case for sodium-ion, particularly for mass-market EVs.

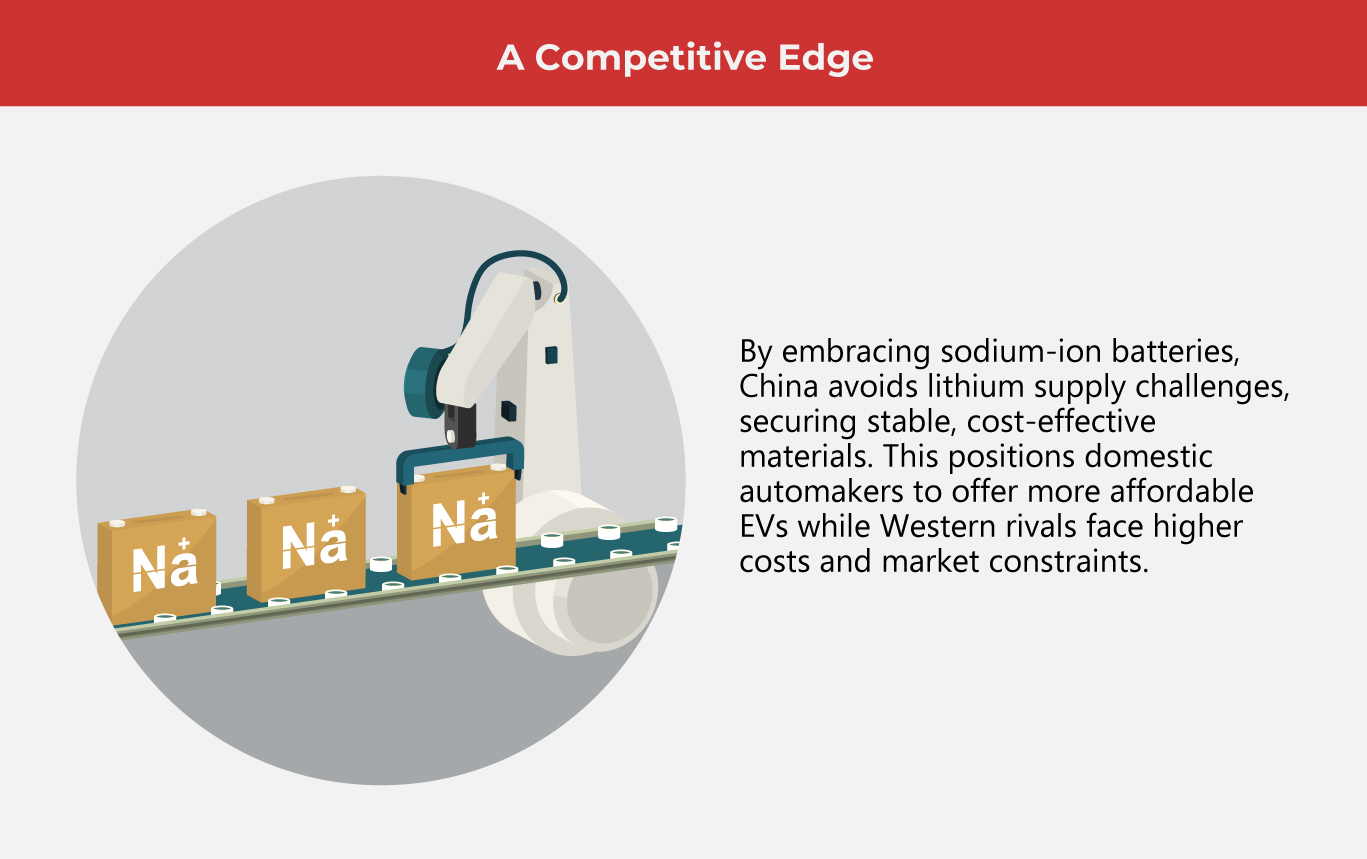

However, sodium-ion technology is not being written off by everyone. In April 2025, China-based CATL used its first-ever “Super Tech Day” to signal confidence in the chemistry, unveiling its Naxtra line of sodium-ion batteries designed for EVs. The announcement marked a shift from lab-scale development to product testing at commercial scale, with CATL positioning the technology as ready for real-world deployment rather than long-term experimentation.

The Naxtra batteries, scheduled for mass production in December 2025, are engineered to operate in extreme conditions, from –40°C to +70°C. The cells achieve an energy density of 175Wh/kg—on par with lithium iron phosphate batteries—and are capable of supporting driving ranges of up to 500 kilometers on a single charge. Those specifications place sodium-ion closer to mainstream manufacturing markets than many critics had anticipated.

As the world’s largest battery maker, CATL’s move carries weight beyond China. By focusing on scalability, cost control, and lithium-free materials, the company is targeting affordable EV segments often overlooked in the race for premium performance. If adoption follows, sodium-ion batteries could reshape how automakers think about mass-market electrification, pushing accessibility to the forefront of the next phase of electric mobility.

(Also read: Sodium-Ion Batteries: What You Need to Know)

South Korea partners with China

China’s push into sodium-ion batteries is drawing heavyweight partners from across the global manufacturing landscape. State-owned energy and chemicals giant Sinopec has entered a collaboration with South Korea’s LG Chem to develop cathode and anode materials tailored for sodium-ion cells, with a focus on stationary energy storage systems and low-speed EVs. The partnership reflects growing confidence that the technology is moving beyond experimentation and into product validation.

Industry projections cited by Sinopec point to a rapid scale-up ahead. China’s sodium-ion battery market is expected to expand from around 10 gigawatt-hours (GWh) in 2025 to roughly 292 GWh by 2034, implying an average annual growth rate of about 45%. By the end of this decade, China is forecast to account for more than 90% of global sodium-ion battery output, cementing its role as the central hub for production, materials, and supply chains.

Momentum from the materials side has been reinforced by downstream manufacturers. CATL’s decision to move into mass production of sodium-ion batteries underscores rising industry confidence and signals that the technology is approaching commercial readiness. Together, these developments suggest sodium-ion batteries are carving out a credible role in China’s energy transition, supported by coordinated advances across research, manufacturing, and validation at scale.

Germany Accelerates Sodium-Ion Battery Development

Germany is stepping up its efforts in energy storage innovation with the launch of the “SIB:DE FORSCHUNG” project, a collaborative initiative designed to fast-track the industrialization of sodium-ion battery technology. With lithium-ion batteries currently dominating the market, sodium-ion cells are emerging as a viable alternative, offering advantages in cost, safety, and, critically, resource availability. By investing in this technology, Germany aims to strengthen supply chain management and reduce Europe’s reliance on Asian lithium-ion production, enhancing the continent’s energy independence and resilience.

The project, backed by the German Federal Ministry of Education and Research, has received approximately €14 million ($15 million) in funding, making it the country’s largest sodium-ion initiative to date. It brings together 21 core partners alongside 42 additional research and industrial collaborators. Industrial manufacturing expertise is central to the initiative, with seven companies tasked with scaling up production processes while 14 academic institutions focus on developing advanced materials and improving battery performance. BASF coordinates the project, ensuring a seamless transfer of innovations from research labs to industrial-scale production.

By 2027, SIB:DE FORSCHUNG aims to deliver scalable materials that enhance battery energy density and longevity, adapt sodium-ion production to existing lithium-ion manufacturing lines, and produce large-format demonstration cells for product validation in real-world applications.

(Also read: A Deep Dive into China’s EV Empire)

Sodium-Ion batteries: Powering the next energy shift

Sodium-ion batteries offer clear advantages over lithium-ion technology, making them a strong contender in the future of energy storage.

-

Availability

Sodium-ion batteries offer abundant, globally accessible sodium that lowers costs and reduces supply chain risks. Unlike lithium, which is concentrated and costly, sodium’s availability minimizes outsourcing dependencies and geopolitical concerns, making sodium-ion batteries a scalable, cost-efficient solution for industrial and electric mobility applications.

-

Boosted safety

Sodium-ion batteries excel in extreme temperatures, losing just 10% of charge in the cold compared to 30 to 40% for lithium-ion. Lighter and safer, they show low thermal runaway risk and can be transported at zero charge. Thermal cycling tests and thermal analysis confirm their durability and reliable performance across conditions.

-

Ideal for low-voltage battery EVs

CATL’s sodium-ion batteries are ideal for low-speed, urban EVs, offering reliable performance in varied weather and cold starts. Analysis shows that with ranges of 100 to 150 miles and lower costs than lead-acid or lithium-ion alternatives, they make affordable city commuting practical, supporting China’s growing market for budget-friendly EVs.

-

Emerging technologies

Advances in sodium-ion batteries, including scandium-doped cathodes and improved electrolytes, could push energy density beyond 200 watt-hours (Wh) per kg, enough for low-performance EVs. Manufacturing solutions and rigorous testing suggest potential 20 to 30% cost reductions, allowing sodium-ion to capture lithium-iron-phosphate (LFP) market share in urban EVs and energy storage, though lithium-ion remains dominant overall.

-

Flexibility

CATL is advancing hybrid battery packs that combine sodium-ion and LFP cells, allowing automakers to balance cost, performance, and safety. The sodium-ion cells offer 175 Wh/kg energy density and use a cathode made of sodium iron hexacyanoferrate, also known as Prussian white, for reliable and practical EV applications.

-

Suited for stationary energy storage applications

Sodium-ion batteries are poised to replace lead-acid cells in combustion engines and support stationary energy storage, where safety and cost matter most. With performance matching LFP at about 70% of the cost, reduced fire risk, and minimal reliance on imports, sodium-ion is becoming a practical, scalable solution for global energy grids.

Sodium-ion’s road ahead

Sodium-ion batteries face a cautious path to wider adoption. Currently under 1% of the global battery market, their cost advantage over LFP has diminished, with LFP prices falling below $50 per kilowatt-hour. As a result, sodium-ion’s appeal is strongest in applications where safety and specialized performance matter.

Standardization remains a challenge, with multiple chemistries still in play. OEMs remain hesitant to fully commit, slowing large-scale adoption.

Despite these hurdles, major players like CATL and BYD are expanding production, signaling that sodium-ion could carve out a niche in cost-sensitive or safety-critical sectors, even if it does not surpass lithium-ion’s dominance.

As one of the Top 20 EMS companies in the world, IMI has over 40 years of experience in providing electronics manufacturing and technology solutions.

As one of the Top 20 EMS companies in the world, IMI has over 40 years of experience in providing electronics manufacturing and technology solutions.

We are ready to support your business on a global scale.

Our proven technical expertise, worldwide reach, and vast experience in high-growth and emerging markets make us the ideal global manufacturing solutions partner.

Let's work together to build our future today.

Other Blog