Soft Robotics Meets the Deep Sea

Unmanned underwater robots have become vital to exploration, surveillance, and maintenance in harsh marine environments. A growing trend in this field is the use of bio-inspired design, with engineers mimicking the movements of fish and cephalopods to create more agile and adaptable machines. One breakthrough is a tentacle-like robot capable of safely gripping and maneuvering around offshore structures, offering a transformative step forward in inspecting and maintaining the millions of kilometers of subsea infrastructure worldwide. This innovation showcases how expanding engineering capabilities are reshaping the future of undersea operations.

Oceans play a critical role in global sustainability, prompting governments to increase investment in seafloor mapping, naval technology, and marine research. Unmanned underwater robots now drive much of this progress, supporting tasks such as product testing in extreme conditions, mapping seabed terrain, studying marine ecosystems, and locating underwater resources. Their ability to operate in harsh and remote environments makes them indispensable to both science and industry.

To perform such complex work, researchers are turning to soft robotics—flexible machines made from silicone, gels, and other deformable materials that move more like living organisms than traditional metal robots. These bio-inspired systems can bend and adapt to their surroundings, allowing for safer interaction with fragile environments and more accurate measurement of environmental indicators. As the technology advances, soft robotics is redefining how the ocean is explored, monitored, and protected.

Researchers continue to draw inspiration from octopus tentacles to advance underwater soft robotics. At Khalifa University, Federico Renda and his team used octopus-like crawling to model the complex motion of soft robotic systems. Building on this concept, the BioRobotics Institute of Scuola’s Matteo Cianchetti and colleagues developed an eight-armed soft robot with a central control body and flexible limbs designed for gripping and locomotion. Its conical shape and soft materials allow it to grip objects of various sizes, a capability refined through rigorous material testing.

(Also read: Hydra Drones: UK’s New Line of Defense)

The rise of tentacle bots

Under the ocean’s surface, one creature has mastered movement, precision, and adaptability like no other: the octopus. Each arm can sense, explore, and react on its own, gripping prey, navigating tight spaces, and manipulating objects with ease. This remarkable mix of strength and flexibility has captivated engineers.

Inspired by nature’s most versatile limb, a new generation of “tentacle bots” is beginning to emerge, built to bend, grip, and operate with the same fluid intelligence found in the deep.

- Combining bending & suction for versatile gripping

In 2020, engineers from Harvard’s Wyss Institute, the John A. Paulson School of Engineering and Applied Sciences, and Beihang University created a breakthrough octopus-inspired soft robotic arm.

Unlike most robotic grippers that can handle only specific shapes, this flexible, tapered arm uses built-in suction cups to securely grasp objects of all sizes and textures—from fragile eggs to bulky exercise balls. The team studied real octopus arms to measure the ideal tapering angle and movement patterns, then designed a robotic version that combines bending and suction in a single system.

The arm is powered by two simple valves: one controls air pressure to bend the arm, and the other creates a vacuum to activate the suction cups. With this setup, the robot can wrap around objects, lift them, and release them with ease. It excelled in tests involving coffee mugs, thin plastic sheets, test tubes, and even live crabs. Its tapered shape also lets it squeeze into tight spaces, making it useful for visual inspection and underwater retrieval tasks.

This innovation marks a major step toward highly adaptable soft robots that can perform complex product validation, handling delicate and irregular items without needing multiple grippers. The research also offers new insight into why octopus arm shapes vary across species, showing that nature still holds the blueprint for next-generation robotic design.

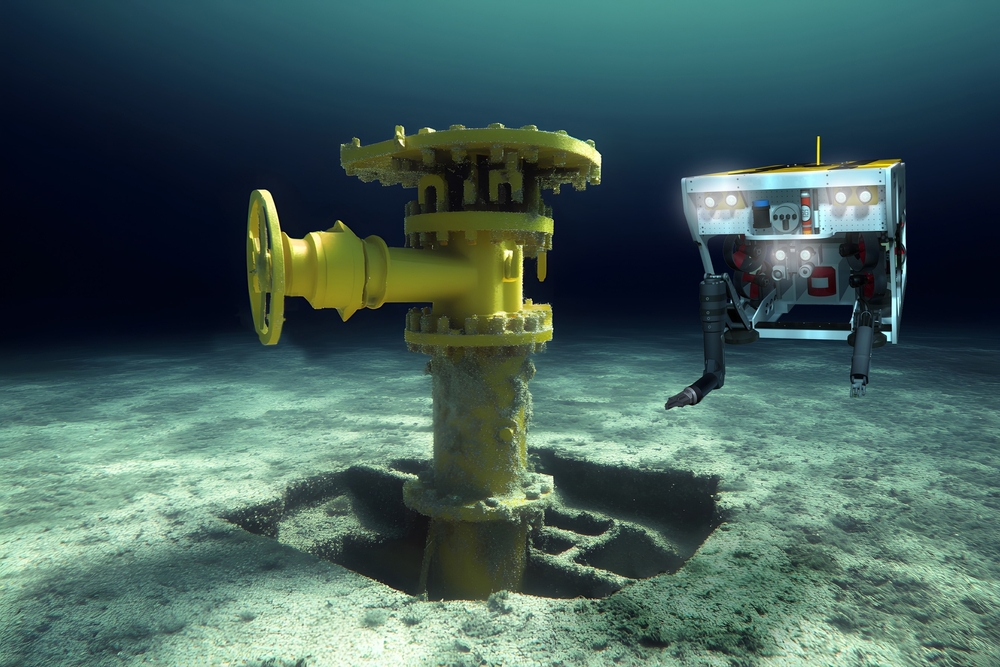

- Built for offshore inspection

A team from the UK’s National Robotarium and Brazil’s Senai Cimatec has engineered a tentacle bot that aims to improve underwater inspection.

Unlike rigid tools that risk damaging sensitive subsea equipment, this one-meter soft manipulator bends and conforms to complex structures, delivering safer, more precise contact. Its development comes at a critical time: global offshore infrastructure is aging, and decommissioning could exceed $100 billion by 2030. By extending the operational life of existing assets, the technology offers enormous economic value while reducing environmental impact.

Engineers achieved this breakthrough using a flexible backbone controlled by tendon-like cables and advanced sensors that track position and shape underwater. Tested in powerful wave simulations, the robot maintained stability under forces up to 300 grams and could correct itself within seconds when disturbed—vital performance in turbulent ocean conditions. Deployed from smaller underwater vehicles, it could inspect offshore wind farms and subsea pipelines without the need for large vessels or human divers, cutting costs, emissions, and risk.

This innovation demonstrates how soft robotics can scale beyond lab experiments and enter new product introductions for the offshore energy sector. By replacing rigid tools with intelligent, adaptable systems, the technology could fundamentally change how the world maintains critical infrastructure beneath the sea.

(Also read: Learn the Top 5 Benefits of AUVs)

A light-sensitive soft robot

Researchers at Rice University have introduced a laser-controlled soft robotic arm that operates without onboard electronics or wiring. It can navigate obstacles and strike moving objects, showing a high degree of precision and flexibility. This capability makes it promising for manufacturing solutions and medical robotics, where gentle handling is essential.

The arm is made from a custom azobenzene liquid crystal elastomer that bends when exposed to blue laser light and returns to its original shape in the dark. Unlike other light-responsive materials that rely on harmful UV light or reset slowly, this one reacts within seconds and supports reliable mechanical test performance.

To achieve complex motion, the team used a spatial light modulator to split a laser into multiple controllable beamlets. Each beamlet targets a specific section of the arm, allowing independent movement similar to an octopus tentacle. This method provides virtually unlimited flexibility, surpassing the limits of traditional rigid robots.

A neural network was trained to predict which light patterns create specific shapes or motions, reducing the need for complicated operator input. Although the current prototype moves in two dimensions, future versions could bend in 3D with added sensors. The researchers believe this platform could advance medical electronics, implantable devices, and soft automation in the industry.

The future of flexible machines

Octopus-inspired soft robots push the boundaries of how machines move, think, and adapt. Their dexterity makes them ideal for handling fragile objects, performing underwater inspections, and assisting in surgery without damaging tissue.

As research rapidly advances, these robots are becoming smarter, safer, and more versatile. From laser-controlled actuators to sensor-rich artificial muscles, engineers are transforming biology into technology. What was once a biological marvel is now a blueprint for future-ready automation, proving that the next wave of robotics may not be made of metal, but of soft, intelligent, and deeply inspired design.

As one of the Top 20 EMS companies in the world, IMI has over 40 years of experience in providing electronics manufacturing and technology solutions.

We are ready to support your business on a global scale.

Our proven technical expertise, worldwide reach, and vast experience in high-growth and emerging markets make us the ideal global manufacturing solutions partner.

Let's work together to build our future today.

Other Blog