Ways to Bounce Back from Global Supply Chain Challenges

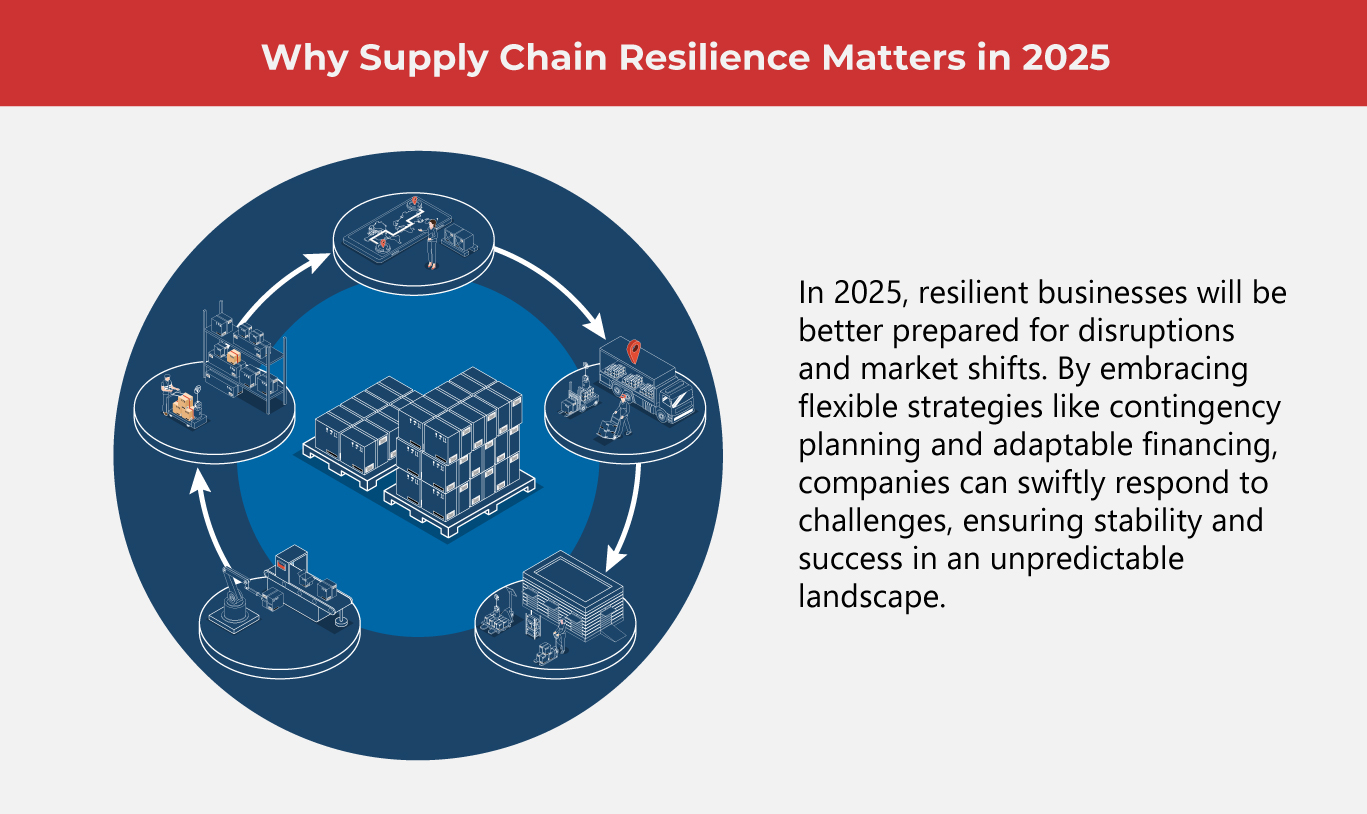

To build a thriving supply chain for 2025, leaders must stay ahead of major shifts and rethink their strategies. Recent years have exposed critical vulnerabilities—from soaring inflation and political instability to extreme weather events and the aftermath of the COVID-19 lockdown—forcing a transformation in supply chain management.

The U.S. administration’s renewed “America First” stance has shaken global supply chains, especially in tech and automotive markets. Rising trade tensions and economic pressure are forcing companies to rethink their global manufacturing plans and international trade ties.

The current U.S. administration relies heavily on economic power as its main tool of influence, favoring short-term gains over traditional diplomacy. Using executive actions, tariffs, and financial pressure, it pursues a protectionist agenda that risks weakening long-term alliances and global stability.

This approach is especially visible in ongoing trade disputes with major partners like Canada, China, and Mexico, where U.S. tariffs and restrictions are impacting the industrial market and straining economic ties.

In response, affected countries are hitting back. Canada has imposed 25% tariffs on over $105 billion in U.S. goods, with Prime Minister Trudeau firmly stating they won’t retreat. Mexico is preparing its own countermeasures, combining tariffs, regulations, and a national strategy called “Plan Mexico” to boost domestic production.

Meanwhile, China opted to push back strategically by delaying some U.S. tariffs by entering talks with President Trump. Nevertheless, tariffs ranging from 10% to 15% were applied to approximately $14 billion worth of American energy and agricultural exports, dimming hopes of averting a full-scale trade standoff between the two largest global economies.

(Also read: Can Trump Break the EV Industry?)

What’s ahead: 8 supply chain trends for 2025

As the global landscape continues to evolve, understanding the key shifts in supply chains will be crucial for harnessing their full economic value.

-

Global financial volatility

This year is marked by growing economic unpredictability, creating significant challenges for supply chains around the world. Factors such as inconsistent inflation patterns, erratic oil costs, and evolving trade regulations contribute to a constantly evolving environment, which risks destabilizing cost structures and disrupting operational efficiency across industries globally.

-

Fluctuating dynamics of international commerce

As mentioned, the new U.S. administration is shifting trade dynamics. China is bolstering its economy and strengthening ties with neighbors, while the EU is seeking ways to avoid a trade war, including reducing tariffs on U.S. imports and expanding energy and defense purchases, along with new trade deals.

-

Adherence to regulations

The EU's Corporate Sustainability Due Diligence Directive (CSDDD) mandates that large companies identify environmental indicators and mitigate human rights risks. Similarly, the U.S. Uyghur Forced Labor Prevention Act imposes penalties on companies sourcing from regions linked to forced labor.

-

Struggles confronting the tech sector

The electronics sector faces challenges from semiconductor restrictions, hindering manufacturing solutions. Experts criticized tariffs on electronics exports, warning they would raise costs. Meanwhile, Chinese firms like Huawei and Alibaba thrive, driving artificial intelligence (AI) advancements and offering affordable tech for industries like robotics and electric vehicles (EVs).

-

Sustainability goals

The push for sustainability urges companies to adopt eco-friendly practices like reshoring, leveraging the renewable energy market, and conducting environmental tests. These efforts not only ensure regulatory compliance but also meet growing consumer and investor demands for better environmental, social, and governance (ESG) performance.

-

Shifting consumer preferences

Consumers today seek openness, tailored experiences, and eco-friendly practices alongside speed. To meet these demands, supply chains are adopting real-time monitoring and advanced analytics, like material testing, to improve logistics management and reduce waste. Adopting agile logistics strategies enables businesses to meet evolving demands while maintaining a competitive edge.

-

Workforce gaps

The retirement of baby boomers and a shortage of skilled replacements have intensified labor shortages, particularly in the logistics and manufacturing sectors. Attracting Gen Z has proven difficult, as many seek tech-driven, flexible careers. To cope, companies are investing in automation and upskilling initiatives to maintain operational efficiency amid a tightening labor market.

-

Cybersecurity

The World Economic Forum identifies supply chain interdependencies as a leading factor in cyberspace's increasing complexity, with vulnerabilities in interconnected systems posing significant risks. Additionally, the rise of AI-driven cyberattacks, projected to account for 75% of incidents by year's end, underscores the urgency for robust cybersecurity measures.

7 ways to deal with supply chain challenges

With global pressures rising, businesses must adopt smarter, more agile strategies to tackle supply chain issues.

-

Broaden the supply base.

To reduce exposure to supply bottlenecks, companies are working with more regional variety. The “China+1” strategy—outsourcing some operations outside China to avoid overreliance—has expanded into broader diversification efforts. By sourcing from multiple markets and improving traceability, firms gain flexibility and resilience amid risks.

-

Streamline supply chains.

Procurement professionals focus on reducing suppliers to simplify supply chains, which helps improve efficiency and reduce risk. Fewer suppliers mean stronger partnerships, fostering collaboration and innovation. It's also crucial that these suppliers stay updated on technology and global trends. Simplifying supply chains enhances traceability and encourages supplier quality.

-

Strengthen supplier partnerships.

In the future, teams will collaborate more with suppliers on innovation and mutual goals, like improving demand planning and inventory oversight. Companies also aim to enhance supplier development platforms to meet sustainability targets, such as improving product life profiles and hitting net-zero goals.

-

Improve risk identification and response.

Risk management will remain crucial for procurement through 2025, but the approach is evolving. With rising legal requirements and stakeholder demands, procurement leaders must use advanced tools and gather data from multiple sources to identify risks across the supply chain, aiding in product validation and systems integration.

-

Utilize high-level strategic business guidance.

Business leaders are relying more on chief procurement officers (CPOs) for insights into market trends, supporting agility, and driving innovation. The CPOs will focus on anticipating changes, and turning early supply chain signals into actionable information. High-growth companies are using procurement data to drive business success.

-

Adopt advanced technologies.

Embracing technologies like AI, the internet of things (IoT), and automation boosts forecasting, inventory management, and real-time visibility. These cutting-edge tools enable proactive risk identification, faster response to disruptions, and optimized operations. By leveraging data analytics and automation, businesses can streamline processes, reduce costs, and adapt swiftly to market changes.

(Also read: 8 Reasons Why You Should Use AI for Improving Factories)

-

Secure cash flow.

Ensure your business stays agile by maintaining access to capital. Cash flow is crucial for meeting service commitments, especially during seasonal inventory surges. A flexible credit line helps manage fluctuations in demand, allowing you to stock essential products, prioritize manufacturing, or cover expedited shipping costs when necessary.

As one of the Top 20 EMS companies in the world, IMI has over 40 years of experience in providing electronics manufacturing and technology solutions.

We are ready to support your business on a global scale.

Our proven technical expertise, worldwide reach, and vast experience in high-growth and emerging markets make us the ideal global manufacturing solutions partner.

Let's work together to build our future today.

Other Blog