The New Rules of Manufacturing in 2026

US manufacturers may find bright spots in 2026 amid economic headwinds. A sweeping tax and spending law known as the One Big Beautiful Bill Act has introduced business-friendly tax changes that could lower operating costs and spur investment in equipment and growth.

Meanwhile, new trade frameworks with partners such as the UK and Vietnam are beginning to ease manufacturing market uncertainty and expand export opportunities. Coupled with potential interest rate cuts that could reinvigorate demand for industrial goods, these developments offer attractive upsides.

Yet manufacturers are wise to plan for a range of economic scenarios — from continued stagnation to renewed expansion.

Manufacturing in 2026: The 10 trends that matter most

As 2026 unfolds, manufacturing industries are navigating a year of rapid change that will test their ability to adapt, compete, and grow.

-

Improved operational efficiency

Sustained performance is rarely about flashy tech tools and more about how well organizations solve problems, see results, and hold themselves accountable. Over the next two years, companies in every sector will need to shut out the noise of tariffs, rates, labor shortages, and geopolitical risk, and double down on what they can control. That means disciplined daily management, visible performance metrics, team-driven problem solving, and steady improvement routines. Technology still matters, but only after strong processes are in place and ready to scale.

-

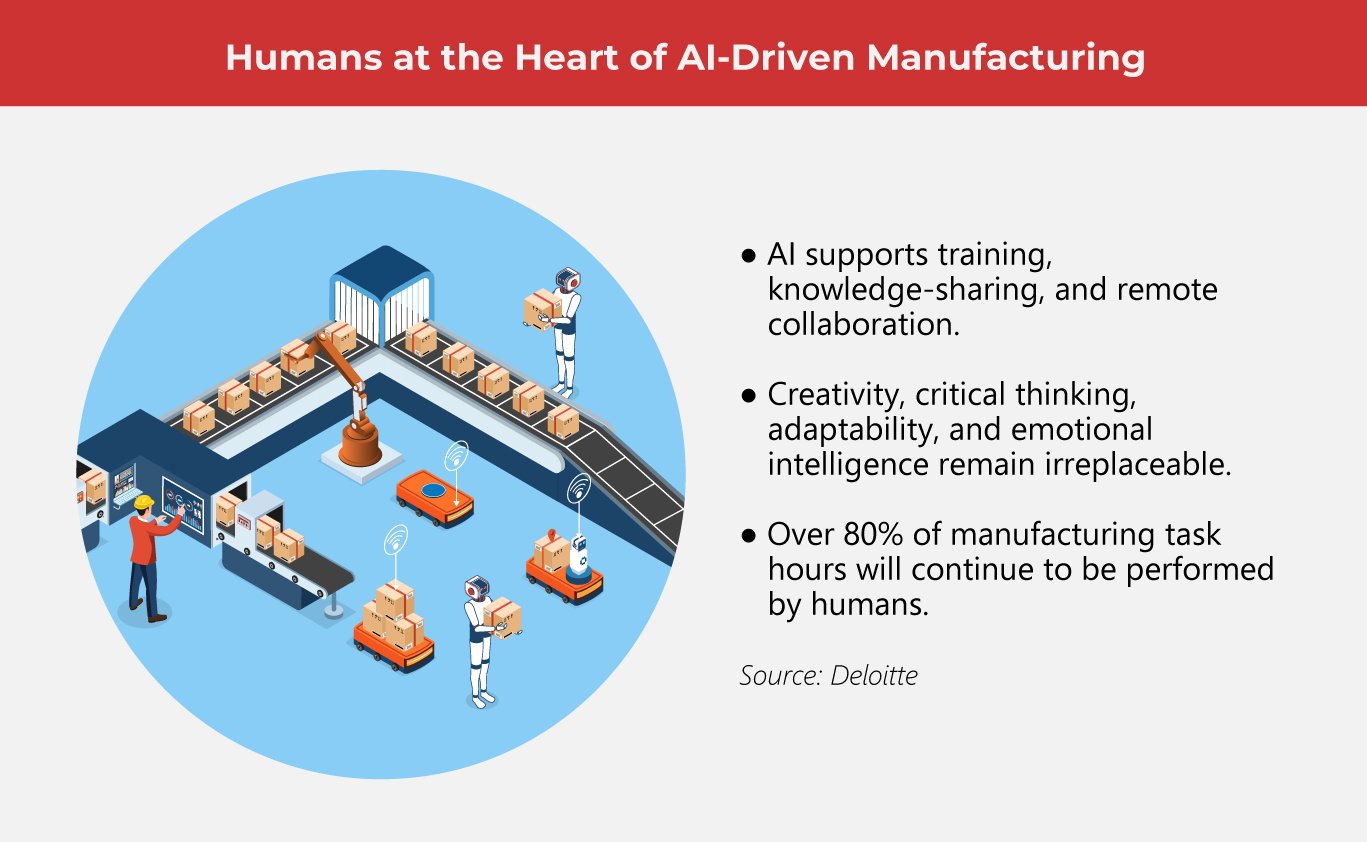

Workforce gaps

The manufacturing industry’s talent crunch shows no signs of easing. Deloitte estimates that by 2030, over two million US factory roles could remain vacant, costing the economy more than US$1 trillion in lost output each year. The shortage is deepening leadership and skills gaps, as nearly a quarter of manufacturing executives across Organization for Economic Cooperation and Development (OECD) nations prepare to retire within five years. With younger workers shunning careers in manufacturing, companies are losing critical knowledge faster than they can replace it.

-

Building manufacturing capabilities

Manufacturers are racing to close widening skills gaps as digital roles in coding, automation, and data analysis evolve faster than talent can keep up. The World Economic Forum projects that nearly four in ten job skills will be reshaped or obsolete by 2030, while 63% of employers already see skills shortages as the biggest roadblock to transformation. With competition for tech-savvy workers intensifying, companies are being forced to rethink hiring, invest in upskilling, and find smarter ways to capture and transfer hard-won knowledge.

-

Digital transformation

Smart manufacturing is moving from ambition to necessity as companies look to stay competitive in an increasingly volatile market. In a 2025 Deloitte survey, roughly 80% manufacturing leaders said they plan to direct at least a fifth of their improvement budgets toward smart manufacturing solutions, highlighting the industry’s growing faith in automation, analytics, and connected systems. Agentic AI is adding momentum, promising gains from supplier sourcing to maintenance and customer support, while middle-market firms steadily accelerate their digital transformation journeys.

-

Smarter supply chain management

After years of disruptions, manufacturers are rebuilding supply chains with resilience as a competitive edge rather than a defensive move. Companies are turning to regional sourcing, reshoring, and dual-supplier models to avoid shutdowns caused by price swings or quality failures. The urgency is clear: in a recent National Association of Manufacturers survey, nearly eight in ten respondents said trade uncertainty is now their top concern. As tariffs and geopolitics reshape global trade, diversified networks and AI-driven risk tools are becoming essential to keep production moving.

(Also read: US-China Tariff Talks: Learn What’s Changed)

-

Securing reliable suppliers

Manufacturers are increasingly turning to nearshoring and diversified sourcing to strengthen supply chain resilience and control costs amid ongoing volatility. US domestic sourcing has surged, while international sourcing also grows, reflecting a push to bring production closer to home. Aluminum sourcing alone has jumped more than 60% since early 2025. Companies are expanding domestic chip partnerships and exploring supplier quality in India and Singapore. Smarter inventory strategies, including 60 to 90-day buffers and AI-driven forecasting, are helping businesses navigate challenges.

-

Business agility

Rapid market volatility is forcing manufacturers to compress planning horizons from several years to just 12 to 24 months and rethink how they operate. Demand is surging in sectors like the automotive market, renewable energy market, and aerospace, outpacing areas such as consumer goods. To stay competitive, companies must embrace flexible production, modular designs, and agile supply chains that respond quickly to customer needs. Digital workflows, integrated product development, and cross-team collaboration are key, enabling faster time-to-market, reduced overhead, and empowered teams focused on high-value work in an increasingly demanding marketplace.

-

AI for competitive survival

AI is emerging as a critical driver in manufacturing, with more than eight in ten executives seeing it as a major growth opportunity. By integrating design, production, and analytics into connected workflows, companies can accelerate innovation and boost efficiency. Predictive maintenance, data-driven process optimization, and cloud-based ERP systems are delivering measurable results. The most successful manufacturers in 2026 will embed AI directly into daily operations, supported by strong data governance, employee training, and scalable, secure platforms tailored to their needs, unlocking new levels of performance and operational insight.

(Also read: How AI & Data Centers Drive Growth)

-

Growing customer standards

Customer expectations are reshaping manufacturing, with more than half of executives noting rising demands for product quality and nearly half reporting faster delivery requirements. Supply chain transparency and personalized service are becoming essential. Aftermarket services are emerging as a key revenue driver, offering higher margins and predictable income. Agentic AI is helping manufacturers optimize parts, schedules, and service levels, enabling proactive planning, reduced downtime, and stronger customer relationships in an increasingly competitive market.

-

Risk management

Cyber risks are rising, from ransomware attacks to intellectual property theft and operational disruptions. Even companies with minimal exposure must strengthen cybersecurity and risk management. In 2026, robust programs will be essential, combining governance frameworks, employee training, and incident response planning. Best practices include regular vulnerability assessments, multi-factor authentication, data encryption, and supplier risk analysis. Proactive measures, such as routine audits, staff education, and collaboration with supply chain partners, can help manufacturers safeguard operations, protect sensitive information, and maintain business continuity in an increasingly digital ecosystem.

Future-Ready Manufacturing

In 2026, manufacturers face a landscape shaped by disruption, digital transformation, and rising customer expectations. Success will belong to those who are prepared—combining resilient supply chains, agile operations, AI-enabled workflows, and a skilled workforce. By investing strategically, embracing innovation, and reinforcing operational fundamentals, companies can turn uncertainty into opportunity and secure long-term growth in an increasingly competitive global market. As one of the Top 20 EMS companies in the world, IMI has over 40 years of experience in providing electronics manufacturing and technology solutions.

As one of the Top 20 EMS companies in the world, IMI has over 40 years of experience in providing electronics manufacturing and technology solutions.

We are ready to support your business on a global scale.

Our proven technical expertise, worldwide reach, and vast experience in high-growth and emerging markets make us the ideal global manufacturing solutions partner.

Let's work together to build our future today.

Other Blog