How IIoT Powers Faster, Smarter Industrial Progress

The IIoT is steadily reshaping the industrial market as companies blend long-established operational practices with advanced digital systems. Often described as a core pillar of Industry 4.0, this shift marks a move toward smarter, more connected production environments. By embedding sensors and smart devices into factories, utilities, and infrastructure, IIoT is helping industrial players unlock new efficiencies and respond faster to changing conditions.

At its core, IIoT enables industrial assets to collect, share, and analyze data in real time. This constant flow of information improves visibility across complex operations, allowing organizations to optimize asset use, reduce downtime, and fine-tune production processes. From factory floors to power grids, connected systems are becoming central to operational decision-making, supported by deeper data analysis and advanced monitoring tools.

Industry 4.0 builds on this connectivity by integrating digital technologies such as automation, remote monitoring, and predictive maintenance into traditional industrial workflows. Reliability testing has also become more critical, as connected systems must perform accurately under demanding industrial conditions.

IIoT operates differently than consumer-focused IoT systems. While consumer IoT links everyday devices, IIoT focuses on heavy equipment and mission-critical systems. By bridging information technology and operational technology, IIoT is redefining how industrial environments function, setting new expectations for performance, resilience, and long-term competitiveness across the global industrial market.

(Also read: Top 15 Benefits of Using IIoT)

Core components of IIoT

Industrial manufacturing is being transformed by interconnected technologies that drive real-time insights and optimize processes.

-

Equipment and devices

Machines in industrial settings rely on smart devices and controllers to collect, process, and transmit data, supporting test and system development. Sensors, actuators, gateways, and embedded systems provide real-time insights, while Programmable Logic Controllers

and industrial PCs manage operations and automate processes. Together, they enable efficient monitoring and seamless communication across industrial networks.

Software drives operational efficiency by turning raw data into actionable insights. User-friendly dashboards and interactive interfaces help operators monitor processes intuitively, while cloud-based platforms centralize data management. This approach speeds analysis, improves decision-making, and allows industrial organizations to boost workflows, reduce delays, and maximize performance across complex operations.

-

Reliable IIOT foundations

IIoT relies on a strong infrastructure of physical devices and digital networks to connect systems and machines. Through careful design and engineering, networks like Wi-Fi, Ethernet, and Low-Powered Area Wide Network (LPAWN) transmit data to cloud or edge platforms. This setup creates flexible and dependable IIoT systems that support efficient operations and real-time monitoring.

-

Sensors

Sensing devices gather real-time information from machinery and production lines, allowing equipment like industrial robots to navigate and operate autonomously. Combined with edge computing, these devices process data locally, reducing delays and limiting data transfer. Applications such as temperature monitors help track machine health, trigger maintenance, and prevent overheating.

IIoT in action

IIoT is transforming industries by enabling real-time monitoring and control of equipment, supporting product validation and analytics-based operations.

IIoT empowers factories to achieve manufacturing excellence by using smart devices and sensors to monitor equipment and production in real time. Data collected is analyzed to predict maintenance needs and enhance automation, boosting efficiency, resource use, and product quality across the production line.

(Also read: Factories Made for the Future)

IIoT transforms automotive production by integrating smart sensors that track equipment performance and anticipate maintenance needs. Real-time data analysis supports supply chain management and quality assurance, enabling manufacturers to streamline operations and reduce downtime, while maintaining high standards across production stages.

-

Logistics

From tracking inventory to guiding autonomous vehicles, IIoT is redefining how warehouses operate. Connected sensors enable automated guided vehicles to navigate efficiently, optimize routes, and support faster decisions. The result is streamlined workflows, reduced errors, and a more agile, smart logistics environment that keeps operations running smoothly.

-

Farming

Smart sensors track soil, crop, and livestock conditions, while drones and satellites provide real-time monitoring. These technologies allow farmers to predict yields, detect disease early, and manage large-scale operations efficiently, driving productivity and sustainable agricultural practices.

How IIoT Drives Value

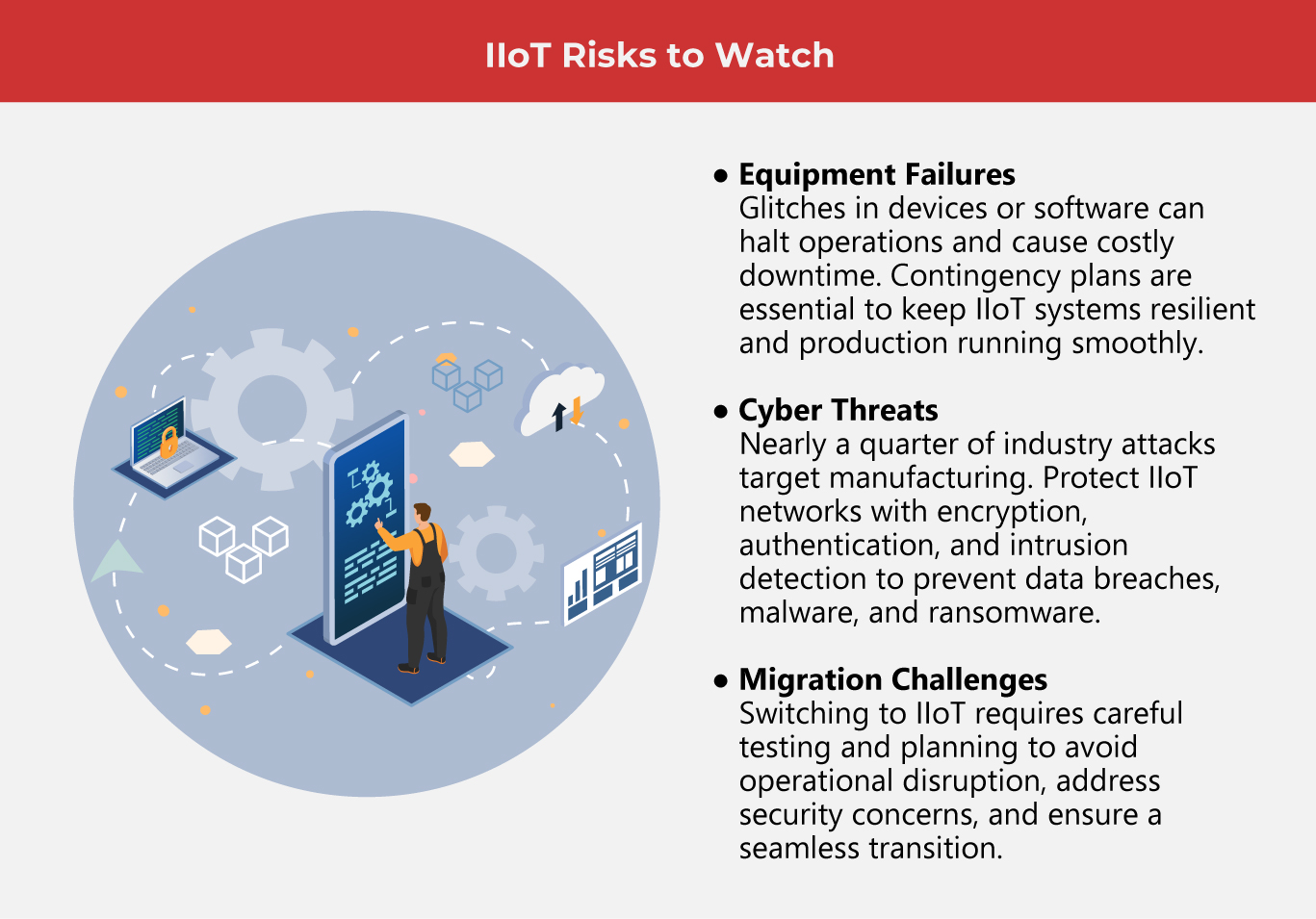

The benefits of IIoT are reshaping global manufacturing, delivering new levels of efficiency, safety, and operational insight. Connected devices and smart sensors allow real-time monitoring of equipment, enabling predictive maintenance that prevents downtime, reduces unnecessary servicing, and maximizes productivity.

IIoT strengthens product testing and quality assurance by ensuring machinery operates within optimal parameters. Continuous monitoring reduces defective output and enables consistent performance, while insights gained at one facility can be replicated across multiple sites, streamlining design for manufacturing processes and accelerating operational improvements.

Safety and security are also enhanced. Industrial environments carry significant risk, yet IIoT systems, including automation and remote monitoring, reduce workplace hazards by performing dangerous tasks without direct human involvement. Sensors detect equipment malfunctions or safety breaches, creating safer conditions for workers and protecting critical assets.

Workflow efficiency benefits as well. Automated systems handle repetitive tasks, freeing human operators for complex, value-added work. Data-driven insights highlight bottlenecks, optimize energy use, and improve decision-making across operations. Factories implementing IoT solutions have reported significant productivity gains, demonstrating how smart monitoring empowers agile, responsive teams.

By combining efficiency, safety, and data-driven decision-making, industrial IoT allows manufacturers to optimize operations, enhance labor productivity, and maintain high-quality output.

Looking ahead: The future of IIoT

As IIoT evolves, organizations increasingly expect platforms to deliver meaningful analysis rather than just raw data. AI and machine learning are reshaping operations, making analytics an operational necessity. Companies that integrate real-time intelligence into workflows and use data to drive decisions and actions will gain a clear competitive advantage in industrial innovation. As one of the Top 20 EMS companies in the world, IMI has over 40 years of experience in providing electronics manufacturing and technology solutions.

As one of the Top 20 EMS companies in the world, IMI has over 40 years of experience in providing electronics manufacturing and technology solutions.

We are ready to support your business on a global scale.

Our proven technical expertise, worldwide reach, and vast experience in high-growth and emerging markets make us the ideal global manufacturing solutions partner.

Let's work together to build our future today.

Other Blog